▏Introduction

The Advanced Laboratory Plastic Granulator is an innovative Small-Scale Pelletizing Machine designed for research and development, academic applications, and small-batch production. With a robust automated control system, this Lab Granulator ensures uniform particle size, optimizing material consistency and experimental precision.

▏Key Features

Precision Cutting Mechanism: Achieves superior granule consistency for reliable analysis.

Intelligent Automated Control: PLC-based touchscreen system for seamless operation.

Energy-Efficient Performance: Low power consumption with optimized processing technology.

Compact & Space-Saving: Designed for laboratory and pilot-scale applications.

Versatile Material Handling: Compatible with multiple thermoplastics and composite materials.

Simple Maintenance: Easy-to-disassemble structure for hassle-free cleaning.

Variable Speed Control: Adjustable pelletizing speed to meet diverse research needs.

▏Applications

The Advanced Laboratory Plastic Granulator serves a variety of industries:

Polymer Research & Development – Fine-tuning new material compositions.

Higher Education & Training – Demonstrating plastic granulation techniques.

Industrial Quality Assurance – Enhancing consistency in plastic processing.

Biomedical Innovations – Developing specialized plastic-based medical components.

Prototype Production – Creating small-scale test samples for evaluation.

▏Advantages of Our Experimental Granulation Equipment

| Benefit | Description |

| Highly Precise Granulation | Maintains consistent granule dimensions for laboratory accuracy. |

| Adaptable Processing Settings | Modifiable parameters to suit a wide range of material types. |

| Enhanced Safety Mechanisms | Features overheating protection and emergency shutdown functions. |

| Minimal Material Waste | Reduces polymer loss during small-scale processing. |

| User-Centric Design | Intuitive interface and ergonomic handling for improved usability. |

▏Technical Specifications

| Parameter | Specification |

| Model | LP-200 Lab Pelletizer |

| Cutting Type | High-precision rotary cutter |

| Motor Power | 2.0 kW – 6.0 kW |

| Control Panel | PLC with touchscreen UI |

| Processing Output | 2-15 kg/h |

| Pellet Dimensions | 1-6 mm (adjustable) |

| Heating Element | PID-controlled electric heater |

| Cooling System | Air and water cooling available |

| Power Requirements | 220V/380V, customizable |

| Material Compatibility | PE, PP, ABS, PET, PVC, and more |

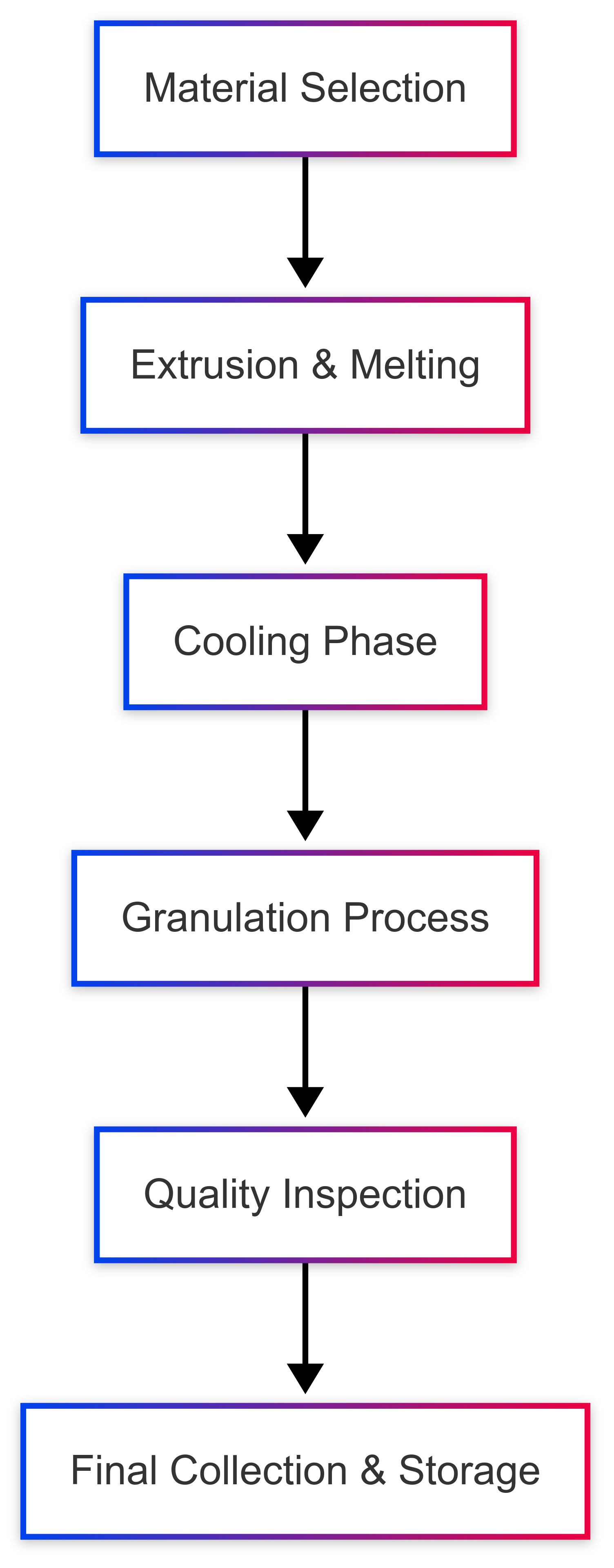

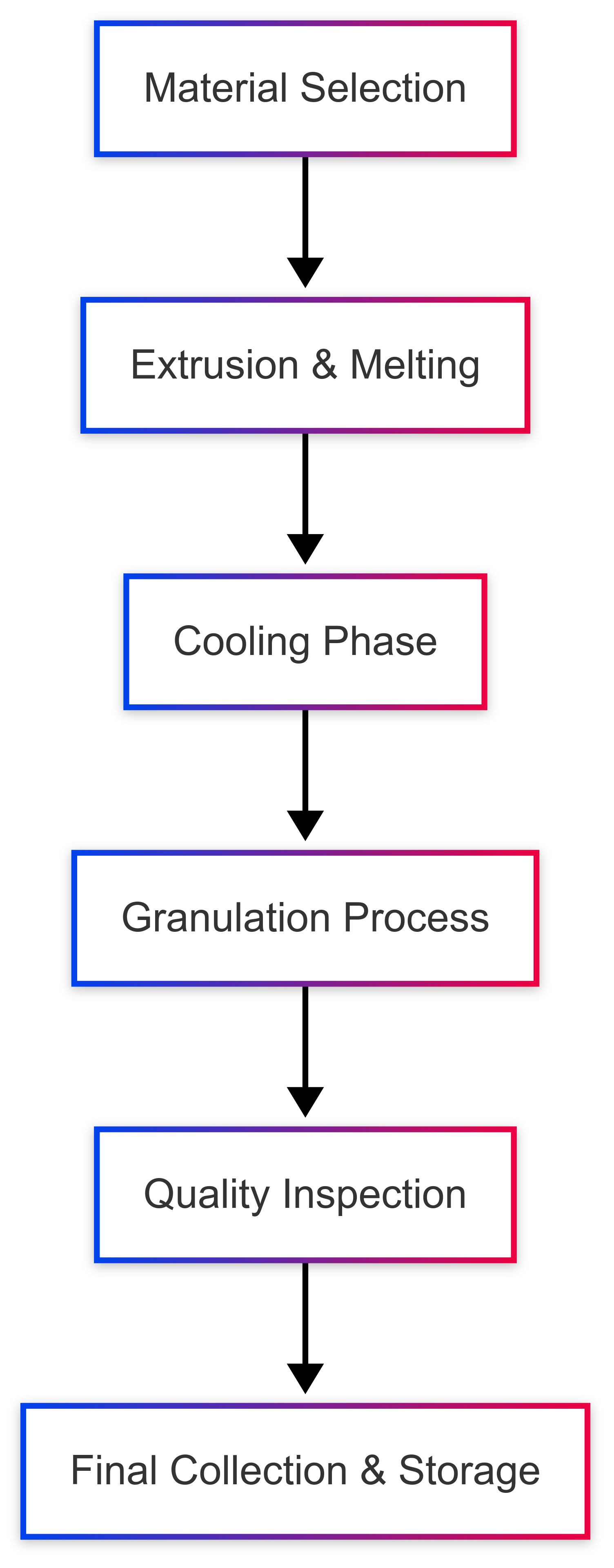

▏Granulation Workflow

Material Selection – Choosing the appropriate plastic compound.

Extrusion & Melting – Heating and feeding the material into the extruder.

Cooling Phase – Using air or water to solidify the strands.

Granulation Process – Cutting the strands into uniformly sized pellets.

Quality Inspection – Screening granules for precise size distribution.

Final Collection & Storage – Preparing pellets for experimental use.

▏Successful Implementations

University Polymer Engineering Lab

By integrating our Lab Granulator, a top research institution improved polymer development efficiency by 50%.

Sustainable Packaging Startup

Our Small-Scale Pelletizing Machine helped a startup create biodegradable plastic prototypes, enhancing sustainability efforts.

▏Why Partner with Us?

Decades of Industry Experience – Specializing in laboratory-scale plastic processing equipment.

Tailored Granulation Solutions – Customizable configurations to match specific research needs.

Comprehensive Support Services – Technical assistance and after-sales care.

Competitive Market Pricing – High-quality products at cost-effective rates.

Rapid Production & Delivery – Streamlined logistics for prompt order fulfillment.

For laboratories, educational institutions, and research facilities, the Advanced Laboratory Plastic Granulator is the ideal Experimental Granulation Equipment to achieve superior uniform particle size and material processing precision. Contact us today to explore how our Small-Scale Pelletizing Machine can enhance your plastic granulation capabilities.