Ut global vestibulum continues movere ad smarter et viridius processibus, Plastic Extruder machinis -Core apparatu in plastic processus industria, testatum est unpecedenced technicae breakthroughs. Ex intelligentes automation et IOT integration ad industria-agentibus consilia et Eco-amica innovations, novam generatio extruder machinis agit in industria deinceps cum celeritate et efficientiam. Hoc articulus erit explorare tardus technological progressiones, analyze quomodo quisque innovation amplio productio efficientiam et uber qualitas, et providebit insights in futurum trends, servientes sicut practical duce ad vestibulum conatibus.

I. Overview of Technicae Evolution In Plastic Extruders

Cum inceptione, plastic extruditoribus evolved a simplex mechanica cogitationes altus automated, intelligentes systems. Traditional Extruders Fideles in basic mechanica agites et temperatus imperium systems, dum modern extruditores integrate provectus est, automation control, et efficientem calor translationis technology ad formare novum exemplar digital, networked, et intelligentes productionem.

1.1 historical evolution

Primo generatione, manual operatio cum basic temperatus moderatoris; humilis efficientiam et repugnans uber qualitas.

Secundi Generat: Introduction of PLC control systems; Automation melior sed cum limitata realis-vicis notitia collectio et feedback.

Tertio generatione plena intelligentes imperium integrating IOT, Digital Didymus, et Predictive Technologies ad precise temperatus imperium et realis-vicis vigilantia.

1.2 Market Overview

Hodie, in global foro pro plastic extruder machinis est subeunda upgrade fluctus. Ducens manufacturers sunt launching novum extruditores et intelligentes et Eco-amica features, propellentibus totum industria ad magis efficient, humilis-navitas, et environmentally sustineri res.

II. Advances in intelligentes automation et imperium systems

2.1 dolor PLC et Imperium Algorithms

Moderni Extruders late usus Smert PLC control Systems quod incorporate provectus algorithms ad pressius adjust et monitor clavis parametri ut temperatus, pressura, et fluunt rate. Hi systems non solum statim adjust productio occasus sed etiam praedicere potentiale apparatu defectis secundum historical data, significantly reducendo downtime.

2.2 AI-Assisted Decision faciens

Per incorporandi apparatus doctrina et artificialis intelligentia, magna volumina productio notitia potest resolvitur ad intelligentes Diagnostics. Nam exempli gratia, ratio potest statim identify abnormes per sensorem notitia et trigger alerts vel adjust operating modos ut firmum productio.

Key Technologies:

Fuzzy Logica Imperium: Enhances praecisione temperatus et pressura referendo.

Neural Network Algorithms: Praedicunt potential defectis in productionem.

Adaptive Imperium Systems: Optimize processus parametri in realem tempus.

III. Applicationem IOT et Digital Didymus Technologies

3.1 IOT Data Books

Per installing variis sensoriis ex extruditoribus, realis-vicis notitia super apparatu status et productio environment potest collecta. Haec data est traducitur wirelessly ad nubem platforms ad repono et analysis, providing robust ex subsequent productio opttimization.

3.2 Digital geminae simulation

Digital geminae technology dat societatibus ad creare virtualis exemplar identical ad corporis apparatu. Hoc concedit realis-vicis vigilantia et simulatio analysis of apparatus operatio. Per continuously adjusting virtualis exemplar, productio processus potest esse optimized, enabling predictive sustentacionem et processum emendationem.

3,3 case applications

| Technology |

Application locis |

clavis advantages |

real-mundi exemplum |

| IOT Data Books |

Equipment Cras, Energy Management |

Princeps realis-vicis accurate |

A ducens plastic turba reducitur industria consummatio per X% per IOT Systems |

| Digital Didymus |

Simulatio, processio Optimization |

Mane quaestio deprehendatur, minus sustentacionem costs |

Reducitur productio debugging exolvuntur per XXX% per simulation systems |

| Hai Diagnostics |

Culpa Predictio, Automatic COMPENTURA |

Auctus apparatu stabilitatem, reducitur downtime |

AI ratio Conscidisti apparatu defectum rates per XV% |

IV. Energy-agentibus consilio et viridi technologiae

4.1 Efficientem calefacientis et refrigerationem systems

Novus Extruders capere summus efficientiam heaters et refrigerationem cogitationes ut, cum maintaining uber species, industria consummatio est significantly reducitur. Exempli gratia, usura DC variabilis frequency calentium et altus-perficientur calor exchangers non solum amplio calor transitus efficientiam sed etiam dat intelligentes industria administratione.

4.2 industria, salvis Motors et optimized tradenda

Tardus Extruders communiter uti summus efficientiam, industria, salvis motors et optimized coegi cogitationes, reducendo friction et industria damnum. Cum variabilis frequency agites, machinis potest statim adjust celeritas secundum productionem necessitates, consequi industria savings et emissiones reductionem.

4.3 Eco-amica materiae et redivivus integration

Pulsis environmental sustineri, quidam extruditores autem integrate online compositio et redivivus technologiae, permittens vastum plastica ad recycled directe. Hoc reducit productio costs et sustinet sustineri progressionem.

V. amet cochlea consilia et fluxus alveum optimization

5,1 innovative screw geometria

Unum de discrimine progressiones in consilio in stupra. Per optimizing et ferrum angulus, segmentum consilio et materiam electionem novi cochlea consilia amplio mixtionem et homogenization dum reducendo tondendas copias, minuam industria consummatio et extendens apparatus vitae.

5,2 fluxus alveum et fingunt meliorem

Propinqua ad screw consilio est optimization fluxus alveo. Modern Design Software et Simulatio Software Liceat Precise ratio of Liquor Dynamics, enabling Designers ad optimize internus fingunt rivos, reducere fluxus resistentia et mortuos, et augendae uber constantiam et superficies qualitas.

VI. Automated Cras et data Feedback Systems

6,1 online vigilantia platforms

Integrating est online magna suggestus concedit realis-vicis ostentationem ex apparatus operatio status, productio data, et industria consummatio, providing administratione cum patet notitia visualization et consilium auxilium. Per haec instrumenta, anomalias potest esse cito identified et addressed.

6,2 data feedback et processu adjustments

Ex colligendis extensive historica data, systems potest aedificare database de vexillum processus parametri continue update per feedback. Data-repulsi referendo ut magis stabilis apparatus operationes et consistent uber qualitas.

VII. Productio Processus Optimization et intelligentes consilium auxilium

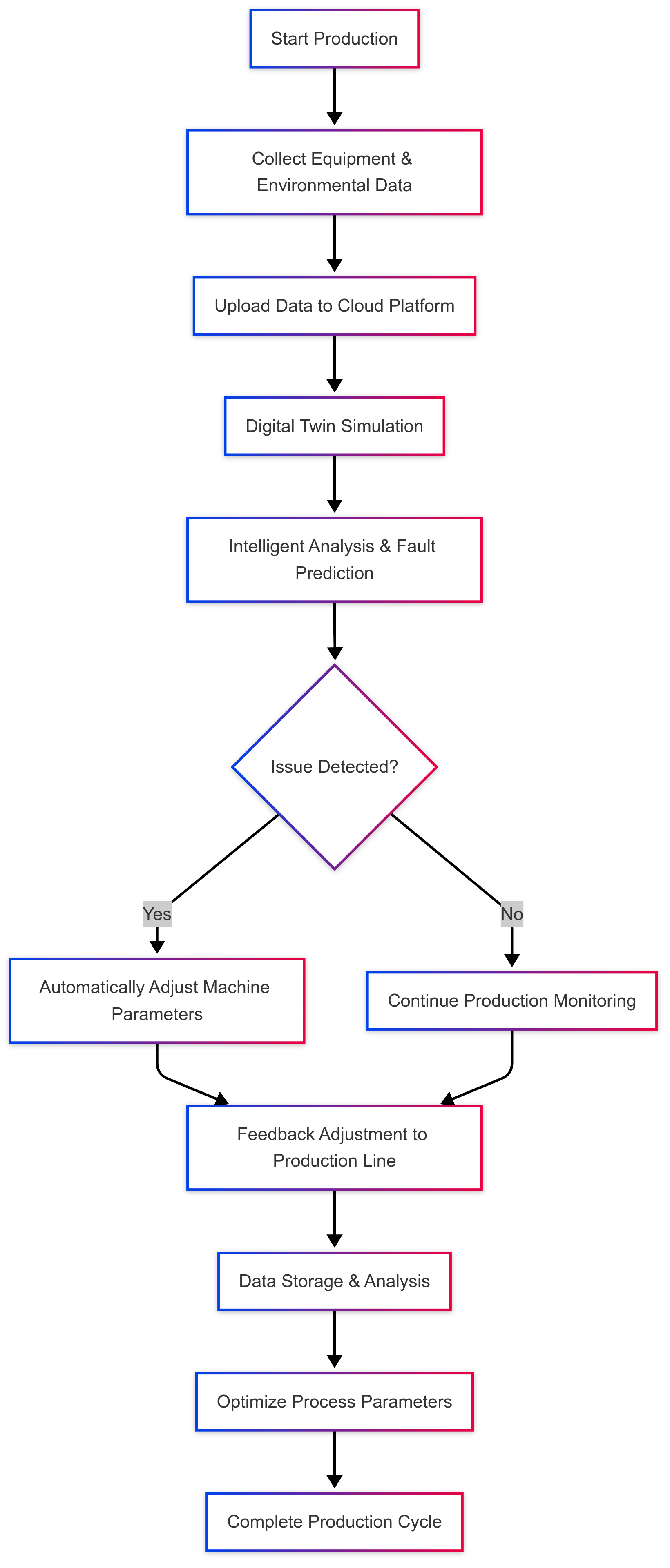

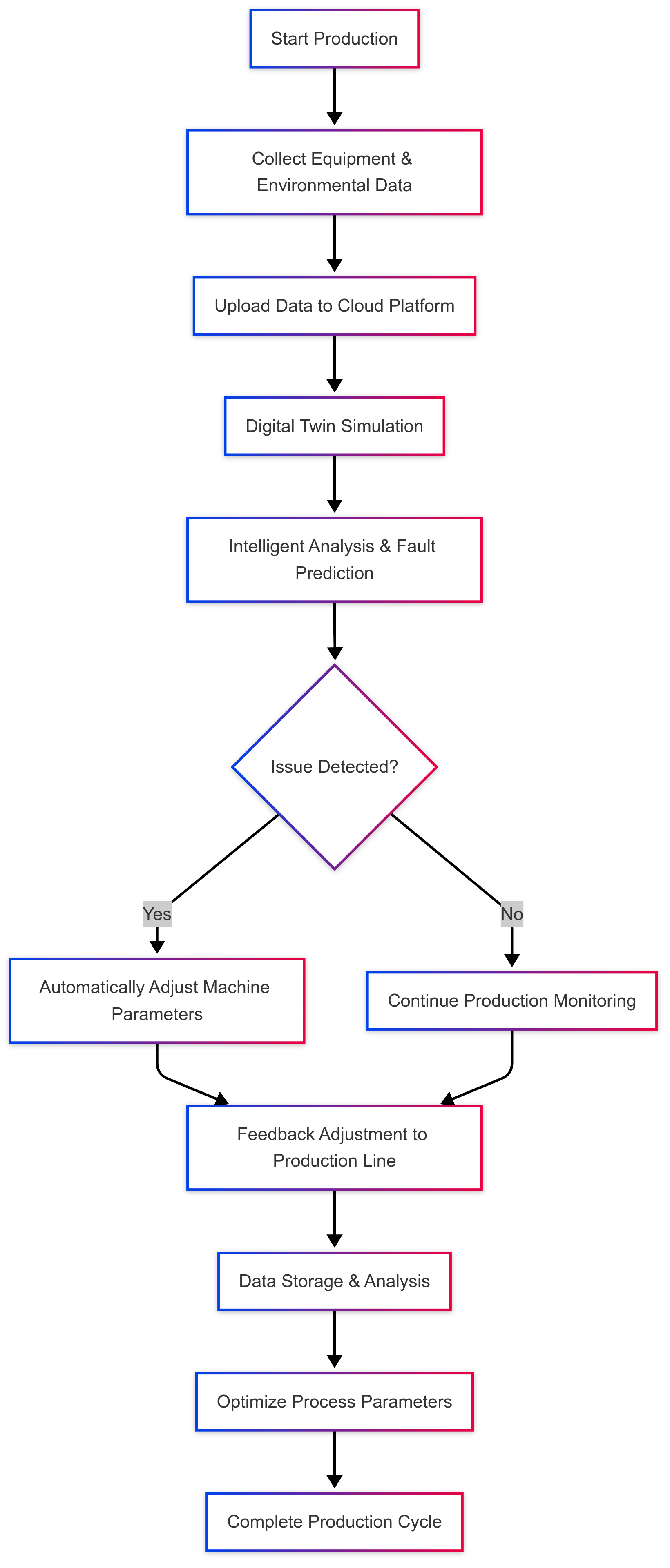

Ad plene integrate haec provectus technologiae in productionem, societates opus comprehensive ratio ad processum Optimization. Et haec flowchart illustrat ad intelligentes consilium Support processus ex data acquisition ad processionem Optimization:

Hoc flowchart demonstrat completum processus-a notitia collection, digital geminae simulation, intelligentes analysis, et automatic adjustments ad ultima processus optimization-providing novum gradu intellectus consilium ad productio administratione.

VIII. Industry casu studiis et technicae applications

Case Study I: Dolor Imperium Ratio in Pe Pipe productio

A ducens plastic manufacturer adoptatus tardus dolor PLC ratio et IOT Cras Platform in Pe pipe productio linea. Cum realis-vicis notitia collectio et Ai-assisted consilium faciens, apparatu defectum rates omissa a XX%, uber constantia improved significantly, et industria consummatio reducitur XV%. Hoc victoria showcases efficaciam integrandi dolor potestate systems ad augendae efficientiam et Eco-amica operationem.

Case Student II: Digital Didymus in PVC Profile productio

In PVC Profile productio, a turba implemented a digital geminae simulatio ratio ad Monitor totam productio linea. By continuously optimizing process parameters through virtual model adjustments, the defect rate dropped from 4% to 1.2%, and the production debugging period shortened by 30%, significantly boosting overall production efficiency.

Case Study III: Innovative Screw Design pro Polymer Composite Processing

Ad oratio challenges in dispensando polymer composites, a manufacturer developed novum segmented cochlea cum optimized ferrum geometria. Experimentalem notitia ostendit an 8-10% melius in productio efficientiam et reducitur industria consummatio comparari traditional stupra consilia.

IX. Market trends et futura expectationes

Sicut dolor vestibulum et viridi technology facti magis prevalent, plastic extruder apparatus technology erit continue evolving ad digitalization, intelligentes imperium, et industria efficientiam. Key Future Trends includit:

Full-Processus Digitalization et intelligentes Decision faciens: More societates et capere magnum notitia et AI Technologies ad Monitor et optimize omnis gradus ad productionem processus.

Vectisque adoption of viridi et industria, salvis technologiae: cum strictorum environmental ordinationes, industria-agentibus machinis et facti amet, driving in industria ad humilis-carbon transformatio.

Customization et modular Design: Futurae extruditores erit focus in modulari consilia, quod potest esse cito customized et upgraded ad occursum diverse foro postulat.

X. Conclusio

Et continua emergentiæ novum technologiae est reshaping plastic extruder apparatus industria. Ex intelligentes automation et IOT integration ad digital geminae simulationes, industria-efficiens consilia, et innovative cochlea et fingunt optimizations, haec progressiones sunt driving significant melioramentis in productione efficientiam et uber qualitas. Manufacturing conatibus debet occupare occasionem ad integrate provectus technologiae, continue optimize productio procedit, et augendae aemulationes. Tantum per permanentis innovation et administratione upgrades potest societates ponere a ducens in ore in acriter competitive foro et consequi summus qualitas, humilis-sumptus, environmentally sustineri productio.

Hoc articulum providet in-profunda analysis de tardus technicae progressiones in plastic extruder machinis et offert practica modos ad applicando his innovations in real-mundi productionem. Ut industria continues amplectere intelligentes et viridis vestibulum, novam generationem plastic extruder machinis et proculdubio ducere in foro in novam era aucta economic et sociali beneficia.