▏Product Vedio

▏Plastic Grinding Machine for Industrial Plastic Waste Recycling

Looking for an efficient and durable solution to reduce plastic waste for reprocessing or reuse? Our Plastic Grinding Machine delivers high-output performance across various industries. Whether you're handling film, pipes, bottles, or molded parts, our machine functions as a powerful Plastic Pulverizer Machine, Plastic Recycling Mill, and Plastic Granulator Equipment, making it the ideal tool for recycling and production efficiency.

Perfect for agricultural film recycling, pipe manufacturers, recyclers, and plastic product producers, this machine helps turn waste into reusable granules or powder for extrusion, injection molding, or pelletizing.

▏Main Features of the Plastic Grinding Machine

| Feature | Description |

| High-speed rotor | Ensures efficient material cutting and uniform granule size |

| Heavy-duty steel structure | Increases machine lifespan and durability under continuous load |

| ️Advanced safety system | Includes overload protection and auto-shutdown mechanisms |

| Adjustable blade design | Easily replaceable and tunable to suit different plastic types |

| Easy cleaning access | Modular parts simplify the maintenance and cleaning process |

| Optional water cooling system | Keeps the grinding chamber cool during intensive operations |

| Intelligent control panel | Digital interface for monitoring speed, temperature, and motor load |

▏Product Photo

▏Customer Case

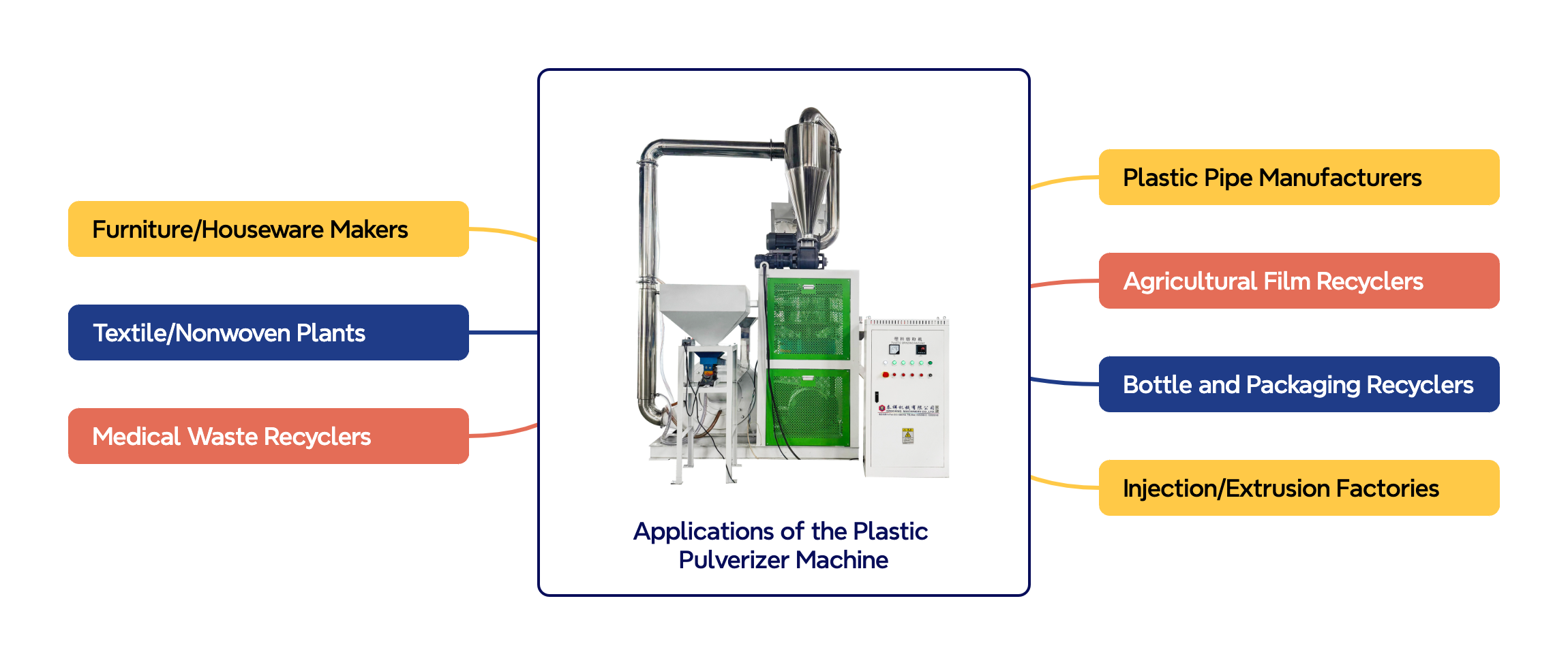

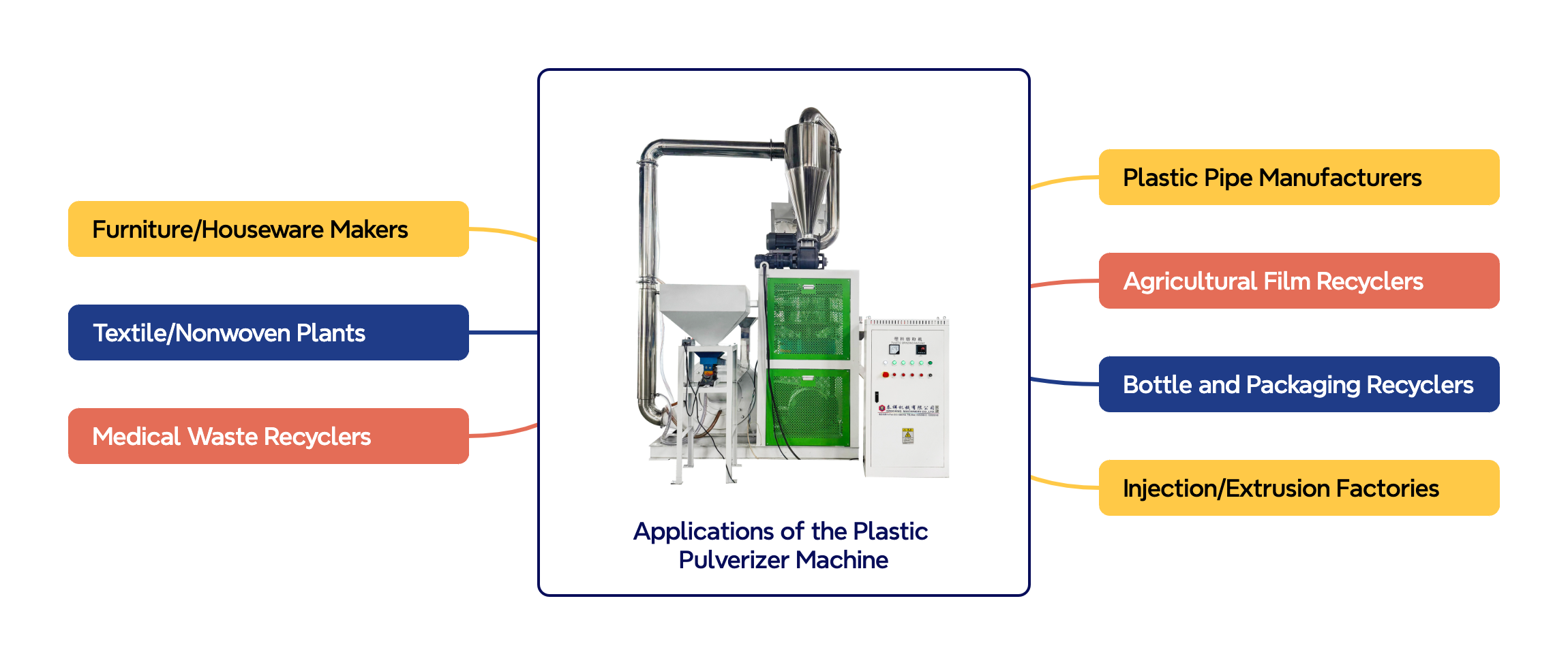

▏Applications of the Plastic Pulverizer Machine

Our Plastic Grinding Machine is used across various industries to process plastic scrap from manufacturing or post-consumer sources:

| Plastic Pipe Manufacturers – PE, PVC, PPR pipe waste grinding |

| Agricultural Film Recyclers – Specialized Plastic grinder for agricultural film recycling |

| Bottle and Packaging Recyclers – HDPE, PET, and PP bottle flake size reduction |

| Injection/Extrusion Factories – Regrinding sprues and defective parts |

| Medical Waste Recyclers – Safe processing of plastic medical disposables |

| Textile/Nonwoven Plants – PET or PP fiber and fabric grinding |

| Furniture/Houseware Makers – Recycling rejected plastic components |

▏Advantages of Our Plastic Granulator Equipment

Choosing the right plastic granulator is key to reducing material loss and increasing ROI. Here’s why ours stands out:

✅ Top Benefits

| High Throughput Rate — Up to 1000kg/h depending on material type |

| Uniform Output Size — Adjustable mesh size from 6mm to 20mm |

| Energy Efficient Motor — Low energy consumption per ton |

| Low Dust Operation — Sealed grinding chamber reduces pollution |

| Versatile Feed Capability — Handles film, hard plastic, pipes, etc. |

| Customizable Blades — V-type and claw blades available for different materials |

| Noise-Reduction Housing — Optional silent housing for factory environments |

▏Technical Configuration

| Component | Specification |

| Main Motor Power | 15kW - 75kW (depending on model) |

| Rotor Diameter | 300mm – 600mm |

| Blade Type | Claw / Flat / V-type (customizable) |

| Crushing Chamber | Sound-proof with double-wall steel |

| Mesh Size Range | 6mm – 20mm (replaceable screen) |

| Hopper Design | Automatic feed / Manual feed options |

| Cooling System | Water or air-cooled (optional) |

| Control System | PLC Intelligent Panel with Alarm |

| Output Capacity | 300kg/h – 1000kg/h |

| Voltage | 380V / 3 Phase / 50Hz (customizable) |

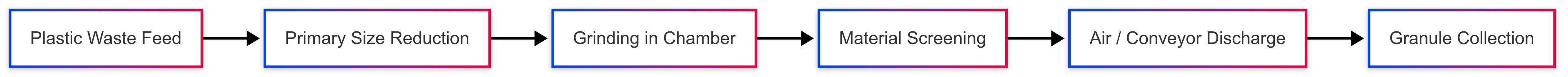

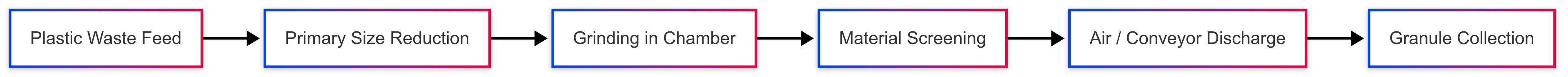

▏Plastic Grinding Machine Production Flow

Here's a step-by-step overview of how our machine turns plastic waste into reusable granules or powder:

You can integrate the machine with:

| Conveyor belts for auto-feeding |

| Dust extractors |

| Storage silos |

| Pelletizing or extrusion equipment |

▏Customer Success Stories

| Case Study 1: Agricultural Film Recycling Plant (India)Problem: Struggled with dirty and bulky LDPE films

Solution: Installed our Plastic grinder for agricultural film recycling with water-cooling system

Result: 40% productivity increase, reduced labor cost by 25% |

| Case Study 2: Pipe Manufacturer (Russia)Problem: Needed regrind of HDPE pipes for reuse in extrusion line

Solution: Customized Plastic Pulverizer Machine with claw blades

Result: Saved $50,000/year in raw material costs |

| Case Study 3: PET Bottle Recycler (Turkey)Problem: Inconsistent flake sizes and high dust output

Solution: Upgraded to enclosed Plastic Granulator Equipment

Result: Improved pellet quality and export rate by 15% |

▏Why Choose Our Plastic Recycling Mill?

| Expertise & CustomizationOver 20 years of experience in plastic recycling machinery manufacturing. Tailored blade, motor, and control configurations available. |

| Quality AssuranceAll machines are CE/ISO certified with a rigorous pre-delivery inspection. |

| ️One-Stop ServiceFrom design to installation and after-sales support, we offer end-to-end services with global delivery and onsite training. |

| Excellent Customer Support24/7 multilingual customer support and 1-year warranty with free spare parts. |

▏Related Products You Might Like

✅ Plastic Shredder for Pre-Processing

✅ PVC Pelletizing Line

✅ PET Bottle Washing Line

✅ Plastic Extrusion Line for Recycled Material

▏Get a Free Quote Now!

Ready to upgrade your recycling capabilities? Contact us today to receive a free consultation and personalized quote on our Plastic Grinding Machine.

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping