▏Overview

The PVC pipe expanding machine is a crucial piece of equipment for plastic pipe manufacturing, designed to produce high-precision sockets and flares. Our advanced Plastic pipe belling machine, also referred to as plastic pipe flaring equipment, offers outstanding automation, precision heating, and versatile socketing capabilities. Whether you require a Plastic pipe socketing machine for industrial production or a Plastic pipe expander machine for customized applications, our solution guarantees efficiency, durability, and high output.

▏Core Features of Our Plastic Pipe Expander Machine

Automatic and Intelligent Operation: Streamlines production and reduces labor dependency.

Multi-Mode Socketing: Supports U-type, R-type, and European standard socketing.

Precision Heating Technology: Ensures consistent and uniform pipe expansion.

Robust & Energy-Efficient Build: Optimized for long-term use with low energy consumption.

Adjustable Configurations: Suitable for a wide range of pipe diameters and thicknesses.

User-Friendly Interface: Touchscreen PLC system for seamless operation.

Advanced Cooling Mechanism: Includes air or water cooling for enhanced efficiency.

Enhanced Safety System: Equipped with multiple protection features to ensure safe operation.

▏Applications of Plastic Pipe Expanding Machines

Our plastic pipe flaring equipment is widely utilized in:

Municipal Water Supply and Drainage Systems

Industrial and Chemical Fluid Transport

Underground Sewage Networks

Agricultural and Irrigation Pipe Systems

Power and Communication Cable Protection

▏Competitive Advantages of Our Plastic Pipe Socketing Machine

| Key Feature | User Benefit |

| Automated Efficiency | Minimizes manual labor and speeds up production |

| Versatile Applications | Adapts to multiple pipe types and standards |

| Energy-Saving Technology | Reduces power usage and cuts costs |

| High-Speed Production | Maximizes output without compromising quality |

| Simple and Intuitive Controls | Enhances ease of operation and training |

| Long-Term Stability | Delivers consistent performance with minimal maintenance |

▏Technical Specifications

Heating System: Precision-controlled infrared or electric heating elements

Control Unit: Smart PLC with real-time monitoring

Socket Forming System: Pneumatic or mechanical operation for uniform shaping

Cooling System: Water or air-based rapid cooling unit

Safety Measures: Emergency shutdown, temperature control protection

Pipe Size Range: 20mm – 800mm (customizable options available)

Power Supply Requirements: 220V/380V, 50Hz/60Hz (configurable for global use)

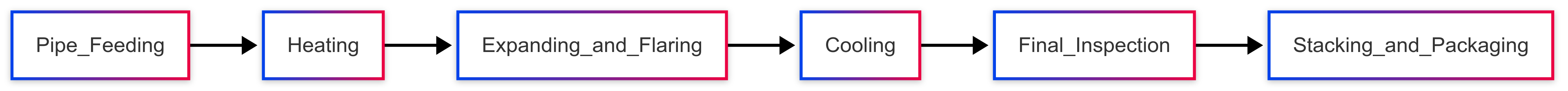

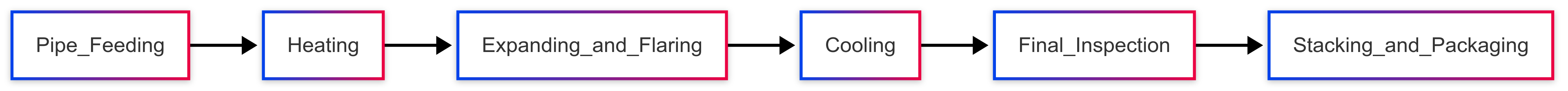

▏Step-by-Step Production Process

Pipe Loading: Pipes are positioned in the machine for processing.

Preheating Phase: The pipe end is heated to optimal expansion temperature.

Socket Forming: The machine expands the pipe end into the required socket shape.

Cooling Stage: Air or water cooling stabilizes the socket structure.

Quality Inspection: Each processed pipe undergoes a thorough quality check.

Packaging & Stacking: Finished pipes are packed and arranged for shipment.

(Illustrative Process Flowchart)

▏Customer Success Stories

Case 1: European Infrastructure Company

A leading European infrastructure firm needed a PVC pipe socketing machine that could handle large-diameter pipes. Our solution enabled them to boost productivity by 35%, improving production capacity and energy efficiency.

Case 2: Agricultural Water Supply Project (Brazil)

A Brazilian agricultural company required a plastic pipe flaring equipment to enhance their irrigation network. With our system, they achieved higher precision and better water flow efficiency, reducing system failures by 25%.

▏Why Partner with Us for Your Plastic Pipe Expander Machine Needs?

Decades of Industry Experience: Over 15 years of expertise in pipe manufacturing solutions.

Reliable Global Support: Dedicated customer service for international clients.

Innovative Automation Technologies: Designed for precision and efficiency.

Fully Customizable Solutions: Machines built to match your production requirements.

Cost-Effective Investment: High ROI with optimized operational costs.

▏Final Thoughts

If you need a PVC pipe expander machine that delivers efficiency, durability, and precision, our PVC pipe belling machine is the ideal choice. Get in touch with us today to discuss your requirements and upgrade your pipe manufacturing operations!