▏Product Vedio

▏Product Introduction

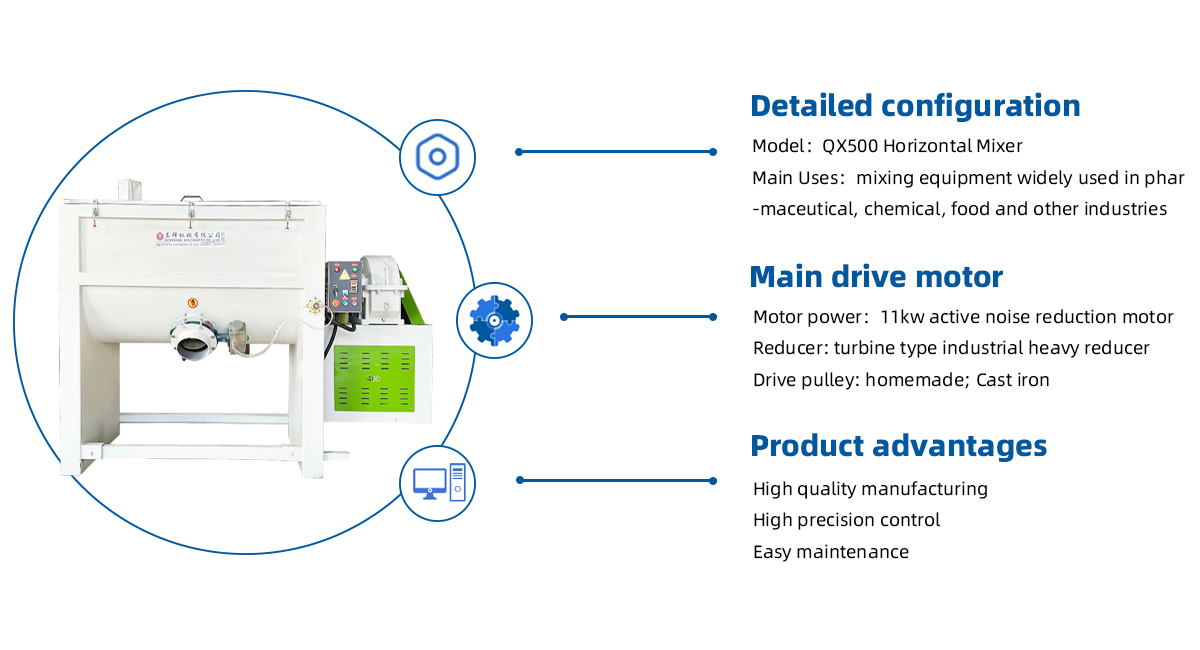

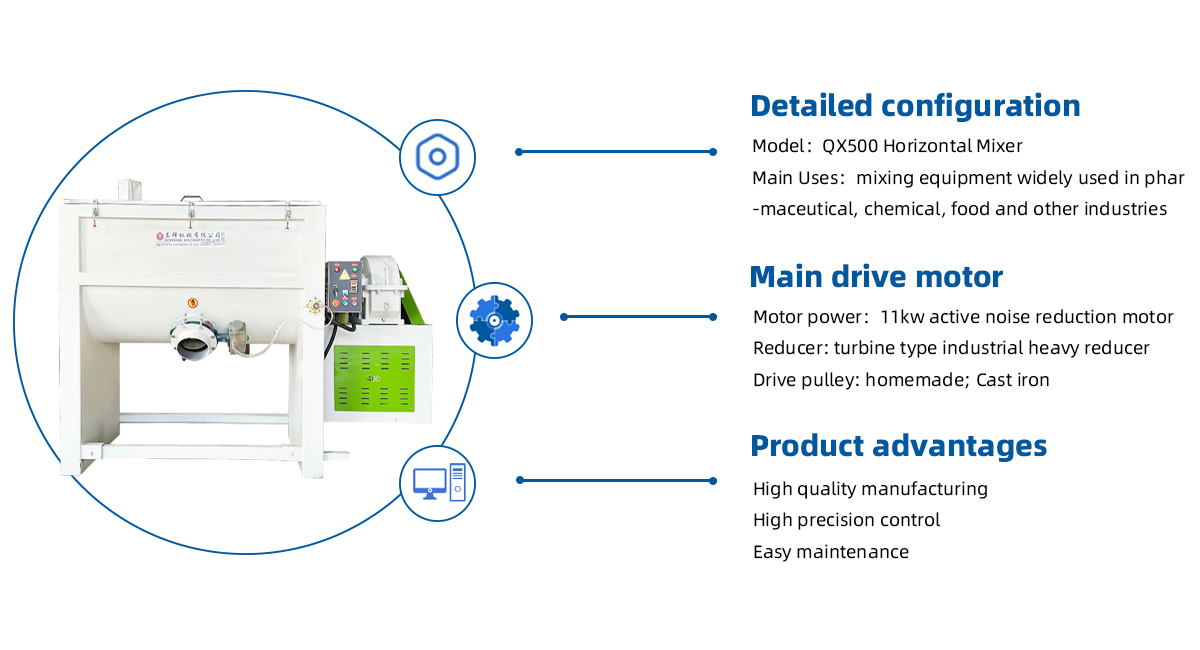

▏Production Details

▏Product Photos

▏Horizontal Mixers: The Ultimate Solution for Efficient and Uniform Mixing

Horizontal Mixers are industrial-grade mixing machines designed to deliver exceptional performance in blending a wide range of materials, from dry powders and granules to viscous pastes and slurries. Renowned for their versatility, efficiency, and reliability, horizontal mixers are widely used in industries such as food processing, pharmaceuticals, chemicals, plastics, and construction. With their unique horizontal design and advanced mixing mechanisms, these machines ensure uniform mixing, reduced processing time, and consistent product quality, making them an indispensable tool for modern manufacturing processes.

Key Features

| 1 |

Horizontal Design for Optimal Mixing |

|

The horizontal orientation of the mixer ensures thorough and uniform blending of materials, even those with varying densities or particle sizes. This design minimizes dead zones and ensures every particle is evenly mixed. |

| 2 |

Versatile Mixing Capabilities |

|

Horizontal mixers are capable of handling a wide range of materials, including dry powders, granules, fibers, and viscous liquids. They are ideal for applications requiring homogeneous blending, such as food ingredients, pharmaceutical formulations, and chemical compounds. |

| 3 |

Robust and Durable Construction |

|

Built with high-quality materials such as stainless steel, horizontal mixers are designed to withstand the rigors of industrial use. Their corrosion-resistant and wear-resistant construction ensures long-term reliability and minimal maintenance. |

| 4 |

Customizable Mixing Tools |

|

The mixers come with a variety of mixing tools, such as paddles, ribbons, and plows, which can be customized to suit specific material types and mixing requirements. This flexibility ensures optimal performance for different applications. |

| 5 |

Energy-Efficient Operation |

|

Designed with energy efficiency in mind, horizontal mixers deliver high-performance mixing with low power consumption, reducing operational costs and supporting sustainable practices. |

| 6 |

User-Friendly Design |

|

The mixers feature intuitive control panels that allow operators to easily adjust mixing speed, time, and other parameters. Safety features, such as emergency stop buttons and protective guards, ensure safe and reliable operation. |

| 7 |

Easy Cleaning and Maintenance |

|

With smooth surfaces and accessible components, horizontal mixers are easy to clean and maintain, reducing downtime and ensuring compliance with hygiene standards in industries like food and pharmaceuticals. |

| 8 |

Customizable Options |

|

Horizontal mixers can be tailored to meet specific production needs, including different mixing capacities, material compatibility, and integration with existing production lines. |

Applications

Horizontal mixers are a versatile solution for a wide range of industries and applications:

- Food Processing: Blending dry ingredients, spices, and flavorings for food products.

- Pharmaceuticals: Mixing active pharmaceutical ingredients (APIs) and excipients for drug formulations.

- Chemicals: Homogenizing powders, granules, and liquid compounds for industrial applications.

- Plastics: Mixing polymer resins, additives, and colorants for plastic production.

- Construction: Blending cement, mortar, and other building materials.

- Agriculture: Mixing fertilizers, animal feed, and crop protection products.

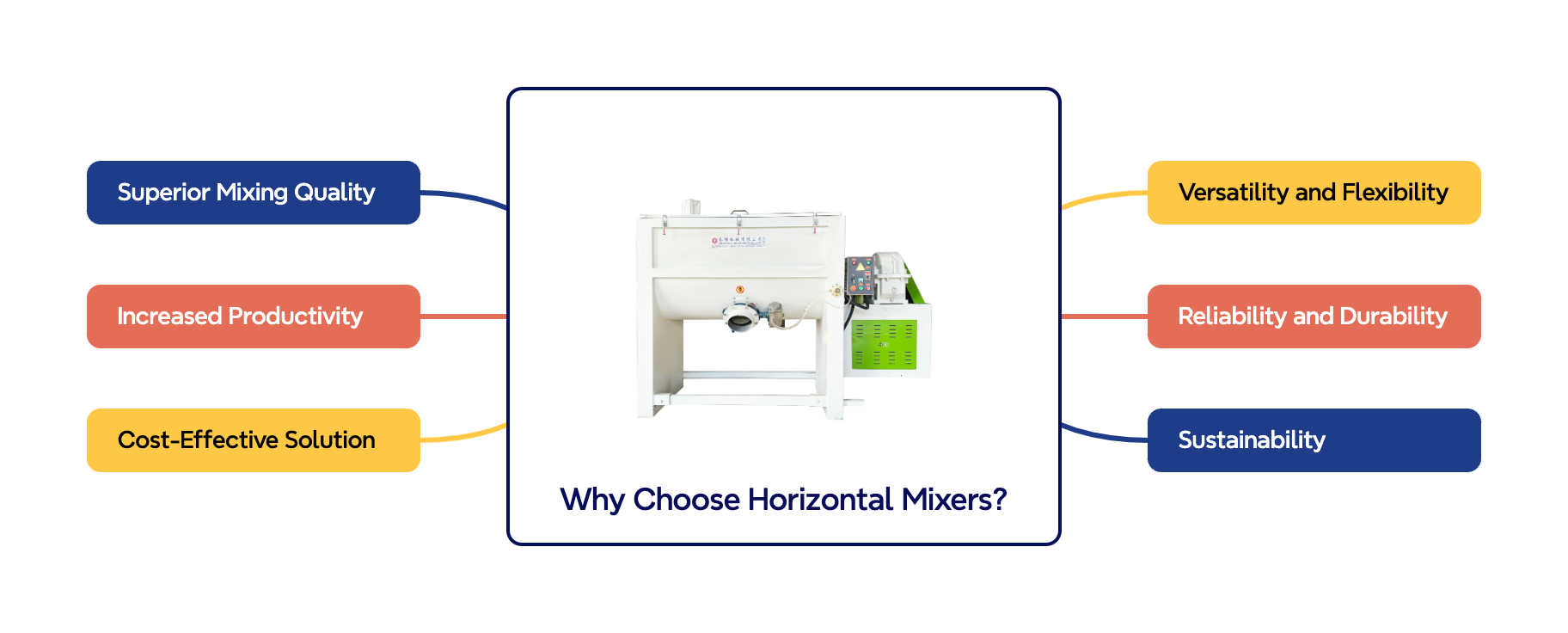

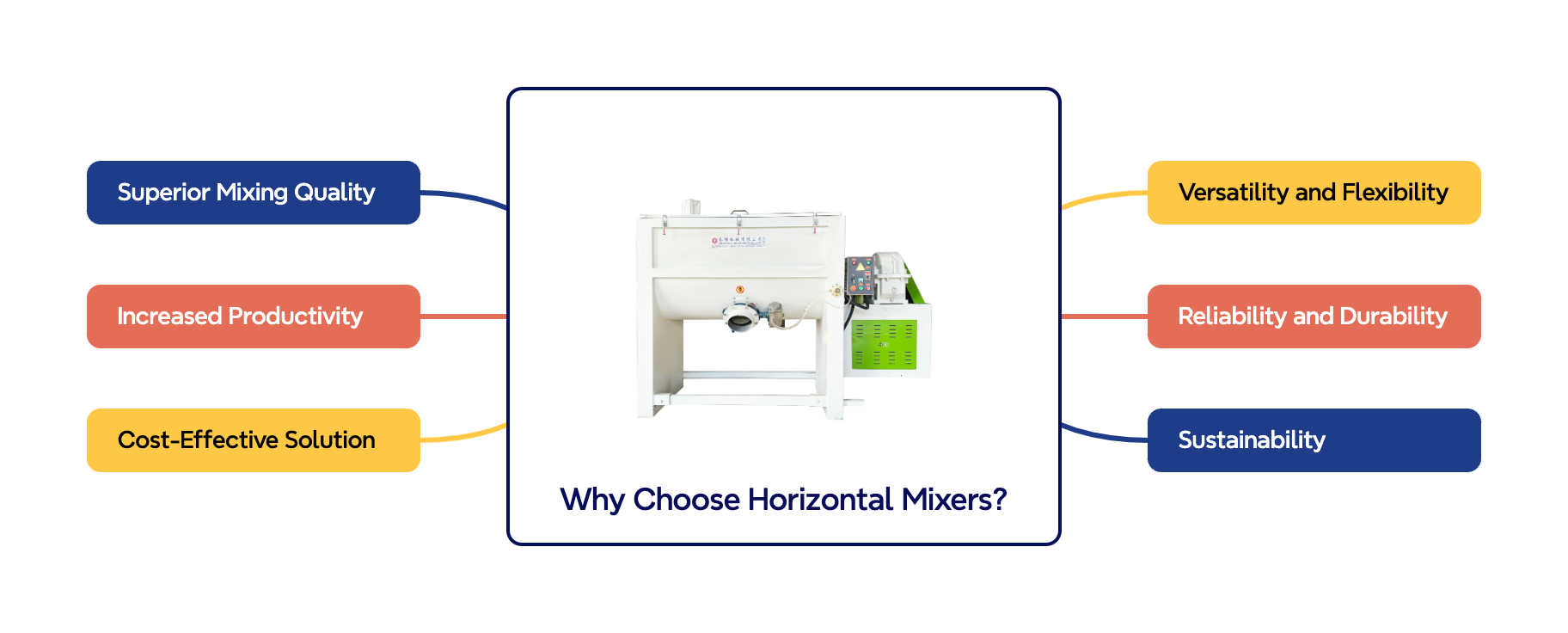

Why Choose Horizontal Mixers?

| 1 |

Superior Mixing Quality |

|

The horizontal design and advanced mixing mechanisms ensure uniform blending, eliminating inconsistencies and improving product quality. |

| 2 |

Increased Productivity |

|

With high-capacity mixing and fast processing times, horizontal mixers enhance production efficiency, allowing businesses to meet growing demand. |

| 3 |

Cost-Effective Solution |

|

The energy-efficient operation and low maintenance requirements of horizontal mixers reduce operational costs and maximize return on investment. |

| 4 |

Versatility and Flexibility |

|

The ability to handle a wide range of materials and customize mixing tools makes horizontal mixers suitable for diverse applications. |

| 5 |

Reliability and Durability |

|

Built to withstand heavy-duty use, horizontal mixers offer unmatched reliability and a long service life, ensuring consistent performance over time. |

| 6 |

Sustainability |

|

By optimizing material usage and reducing waste, horizontal mixers support sustainable manufacturing practices. |

Technical Specifications

- Capacity: Available in various sizes to suit different production volumes.

- Mixing Speed: Adjustable speed settings for precise control over mixing intensity.

- Material Compatibility: Suitable for dry powders, granules, fibers, and viscous liquids.

- Construction Material: High-grade stainless steel (SS304 or SS316).

- Power Supply: Available in standard and customized power configurations.

Horizontal mixers are the ultimate solution for industries seeking to optimize their mixing processes. With their advanced technology, robust design, and user-friendly features, they deliver unmatched efficiency, quality, and versatility. Whether you're blending food ingredients, pharmaceutical formulations, or industrial compounds, horizontal mixers are the ideal choice for achieving consistent and high-quality results.

Invest in horizontal mixers today and experience the perfect blend of innovation, reliability, and performance in your production process!

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping