▏Product Vedio

▏PVC Threading Pipe Extrusion Line

▏Introduction to PVC Threading Pipe Extrusion Line

The PVC Threading Pipe Extrusion Line is an advanced production system designed specifically for manufacturing high-quality PVC (Polyvinyl Chloride) threading pipes. These pipes are commonly used in electrical conduit systems for wiring, plumbing, and telecommunications due to their excellent durability, electrical insulation properties, and corrosion resistance. The PVC threading pipe extrusion line is optimized for efficient, large-scale production while maintaining high standards of quality and precision.

By combining cutting-edge technology with robust engineering, the PVC threading pipe extrusion line ensures consistent pipe quality, uniform thickness, and optimal mechanical properties. It is a perfect solution for manufacturers seeking to produce reliable and durable pipes that meet the demanding needs of industries such as construction, power distribution, and infrastructure development.

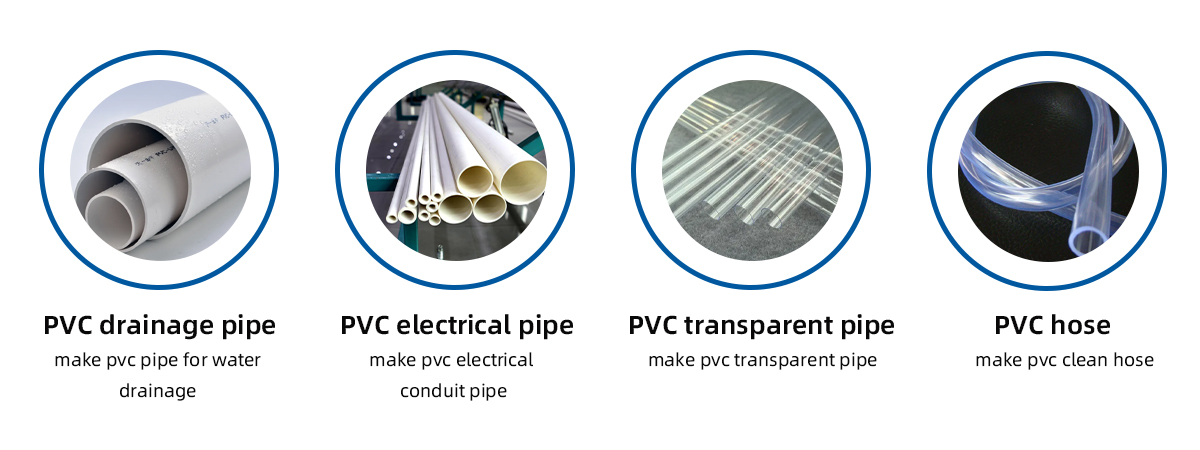

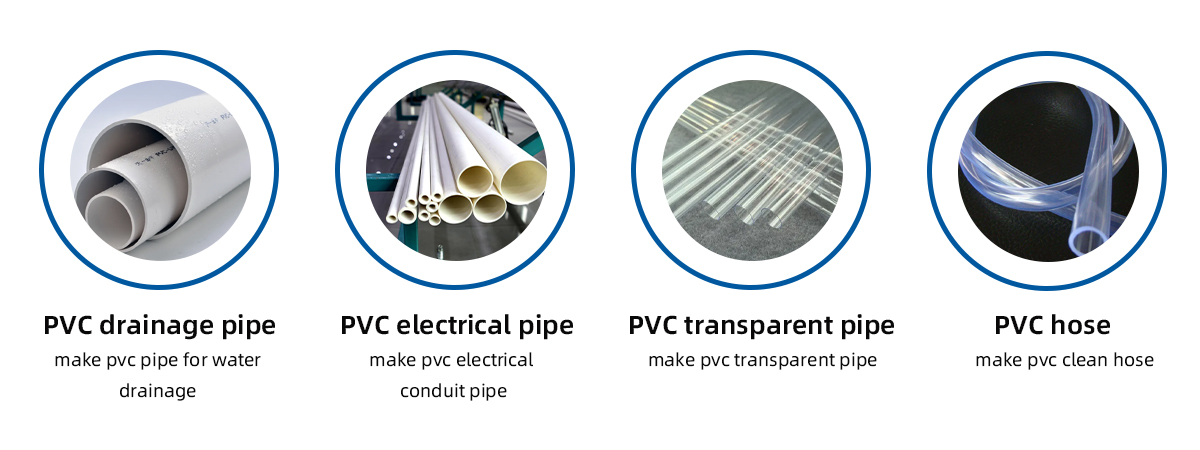

▏Range Of Application

▏Technical Parameters

Pipe size range (mm) | 20-110 | 110-315 | 200-500 | 315-630 |

extruder | SJSZ51/105 | SJSZ65/132 | SJSZ80/156 | SJSZ92/188 |

Main engine Power (kW) | 22 | 37 | 55 | 110 |

Output (kg/h) | 120 | 250 | 450 | 800 |

Maximum production speed (m/min) | 10 | 10 | 3 | 1.2 |

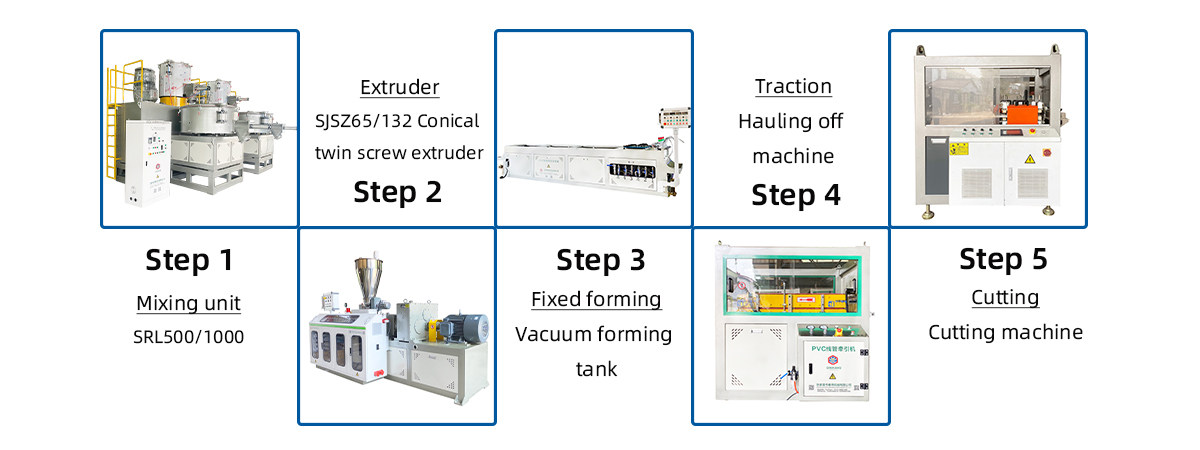

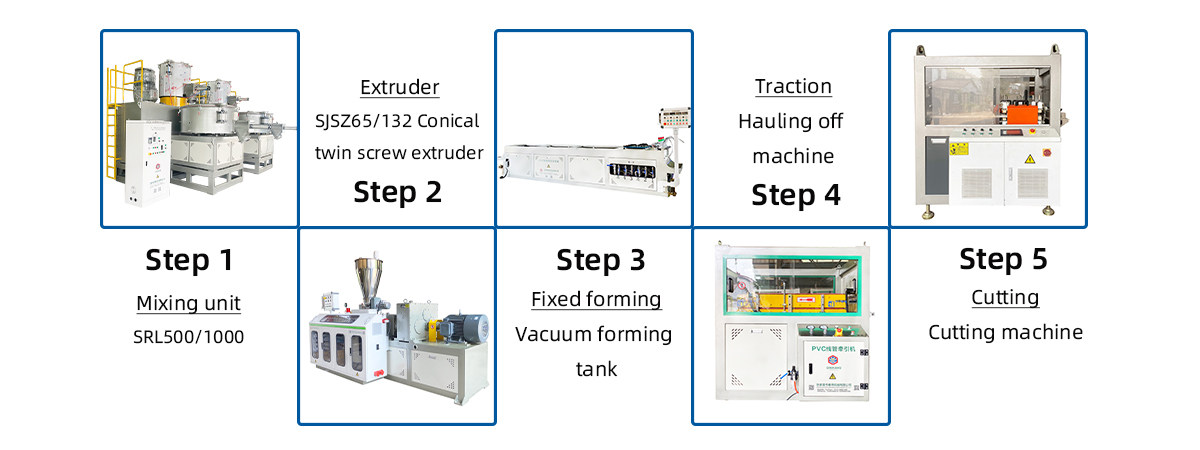

▏Production Procedure

▏Product Photos

▏How the PVC Threading Pipe Extrusion Line Works

| 1. Material Feeding and Melting

The extrusion process begins with feeding PVC resin pellets into the extruder’s hopper. The extruder’s screw and barrel system melt and mix the material under precise temperature and pressure control. The material is evenly plasticized to ensure a consistent and uniform flow of the melted resin, preventing material degradation and ensuring high pipe quality. 2. Extrusion and ThreadingOnce the material is melted, it is forced through the die head, which shapes the material into the desired pipe form. In the case of PVC threading pipes, the die head is designed to incorporate the threading system that forms a uniform thread pattern on the pipe’s outer surface. This threading pattern ensures that the pipes will fit securely with other components during installation. 3. Cooling and CalibrationAfter extrusion, the PVC pipe is cooled and solidified through water baths and air cooling units. The calibration system ensures that the pipe maintains its precise diameter and wall thickness. The pipes are carefully monitored during the cooling process to prevent any deformation, ensuring they meet the required specifications. 4. Haul-Off and CuttingThe haul-off unit continuously pulls the pipe through the extrusion line at a consistent speed. This pulling mechanism prevents any deformation of the pipe and ensures that the final product maintains its shape and integrity. The cutting unit then trims the pipes to the desired lengths with high precision, ensuring clean cuts with minimal material loss. 5. Quality Control and PackagingAfter the pipes are cut, they undergo a quality inspection to ensure they meet the required standards for size, threading accuracy, and overall quality. Any defective pipes are rejected, and the remaining pipes are automatically packaged for shipment. The extrusion line can be integrated with an automated packaging system to streamline the process, ensuring that the finished pipes are securely packed and ready for delivery. |

▏Applications of PVC Threading Pipes

| 1. Electrical Conduit Systems

PVC threading pipes are widely used in electrical conduit systems for protecting wiring and cables. The pipes' excellent electrical insulation properties make them ideal for safely enclosing electrical wires and preventing electrical hazards. The precision threading ensures a tight, secure fit with other fittings, contributing to a robust and reliable electrical infrastructure. 2. Plumbing and Water Supply SystemsPVC threading pipes are commonly used in plumbing applications for both residential and commercial water supply systems. These pipes are resistant to corrosion, chemicals, and high-pressure conditions, making them a durable solution for delivering water and other fluids. The precision threading ensures easy connection with other plumbing components, reducing the risk of leaks. 3. Telecommunications and Data SystemsIn telecommunications and data systems, PVC threading pipes are used to protect cables and wiring from environmental damage. Their insulating properties and resistance to external factors such as moisture, UV radiation, and chemicals make them ideal for safeguarding sensitive communication lines. 4. Industrial Piping SystemsPVC threading pipes are also used in various industrial applications, including the transportation of gases, liquids, and chemicals. The strong mechanical properties of PVC, combined with the precise threading, make these pipes suitable for high-pressure systems and environments where reliability and safety are critical. |

▏Benefits of PVC Threading Pipe Extrusion Line

| 1. High Production Efficiency

The PVC Threading Pipe Extrusion Line is designed for high throughput, allowing manufacturers to produce large quantities of threading pipes in a short period. This high efficiency helps reduce production time and cost per unit, increasing the overall profitability of the manufacturing process. 2. Customization and FlexibilityWith the ability to produce pipes in various diameters, wall thicknesses, and threading profiles, the PVC Threading Pipe Extrusion Line offers flexibility to meet a wide range of customer specifications. This customization ensures that manufacturers can cater to diverse markets and applications. 3. Enhanced Product QualityBy incorporating advanced extrusion and threading technologies, the PVC Threading Pipe Extrusion Line guarantees superior product quality. The pipes produced have smooth surfaces, uniform wall thickness, and precise threading, ensuring a reliable fit with other components and long-lasting performance. 4. Cost-Effectiveness and Energy EfficiencyThe energy-efficient design of the extrusion line reduces operational costs, while its high productivity ensures that manufacturers can meet large-scale demands without compromising on quality. This combination of efficiency and cost-effectiveness makes the extrusion line a sound investment for pipe manufacturers. 5. Low Maintenance and DurabilityThe robust design of the PVC Threading Pipe Extrusion Line ensures minimal downtime and maintenance. The high-quality components used in the extrusion line are built to last, reducing the need for frequent repairs and increasing the overall uptime of the system. |

▏The Future of PVC Threading Pipe Production

The PVC Threading Pipe Extrusion Line offers a cutting-edge solution for producing high-quality PVC threading pipes that meet the demands of industries such as electrical, plumbing, telecommunications, and industrial piping. With its advanced technology, energy efficiency, and customization options, this extrusion line is a reliable investment for manufacturers looking to enhance their production capabilities, reduce operational costs, and deliver superior products to the market.

By incorporating the PVC Threading Pipe Extrusion Line into their manufacturing processes, companies can ensure consistent product quality, increase production efficiency, and stay competitive in the growing global market for PVC pipes.

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping