▏Product Vedio

▏Product Introduction

▏Main Details

▏Product Photos

▏Plastic Pipe Wrapping Machine: Revolutionizing Pipe Protection and Packaging

The Plastic Pipe Wrapping Machine is a cutting-edge industrial solution designed to streamline the packaging and protection of plastic pipes, ensuring they remain in pristine condition during storage, transportation, and handling. Ideal for manufacturers and suppliers in the construction, plumbing, and infrastructure industries, this machine offers unmatched efficiency, precision, and reliability. By automating the wrapping process, it significantly reduces labor costs, minimizes material waste, and enhances the overall quality of pipe packaging.

Key Features

| 1 | Advanced Wrapping Technology |

| The Plastic Pipe Wrapping Machine utilizes state-of-the-art wrapping technology to securely encase pipes in protective materials such as stretch film, PE film, or shrink wrap. This ensures maximum protection against dust, moisture, scratches, and other environmental factors. |

| 2 | High-Speed Operation |

| Designed for high-volume production environments, this machine delivers fast and consistent wrapping speeds, significantly improving productivity and meeting tight production deadlines. |

| 3 | Versatile Compatibility |

| The machine is compatible with a wide range of plastic pipe sizes, diameters, and lengths, making it suitable for various applications, from small plumbing pipes to large-diameter industrial pipes. |

| 4 | Precision and Consistency |

| Equipped with adjustable tension control and precise film feeding mechanisms, the machine ensures uniform wrapping with optimal film tension, eliminating wrinkles and loose ends. |

| 5 | Durable Construction |

| Built with high-quality materials and robust components, the Plastic Pipe Wrapping Machine is designed to withstand the rigors of industrial use. Its corrosion-resistant and wear-resistant construction ensures long-term reliability. |

| 6 | User-Friendly Design |

| The machine features an intuitive control panel with a touchscreen interface, allowing operators to easily adjust settings such as wrapping speed, film tension, and pipe length. Safety features, including emergency stop buttons and protective guards, ensure safe operation. |

| 7 | Customizable Options |

| The machine can be customized to meet specific production requirements, including different wrapping materials, automation levels, and integration with existing production lines. |

Applications

The Plastic Pipe Wrapping Machine is a versatile solution for a wide range of industries and applications:

- Construction: Protecting PVC, HDPE, and PP pipes used in building and infrastructure projects.

- Plumbing: Wrapping pipes for residential and commercial plumbing systems.

- Agriculture: Packaging irrigation pipes and drainage systems.

- Industrial: Protecting large-diameter pipes used in chemical processing, oil and gas, and water treatment facilities.

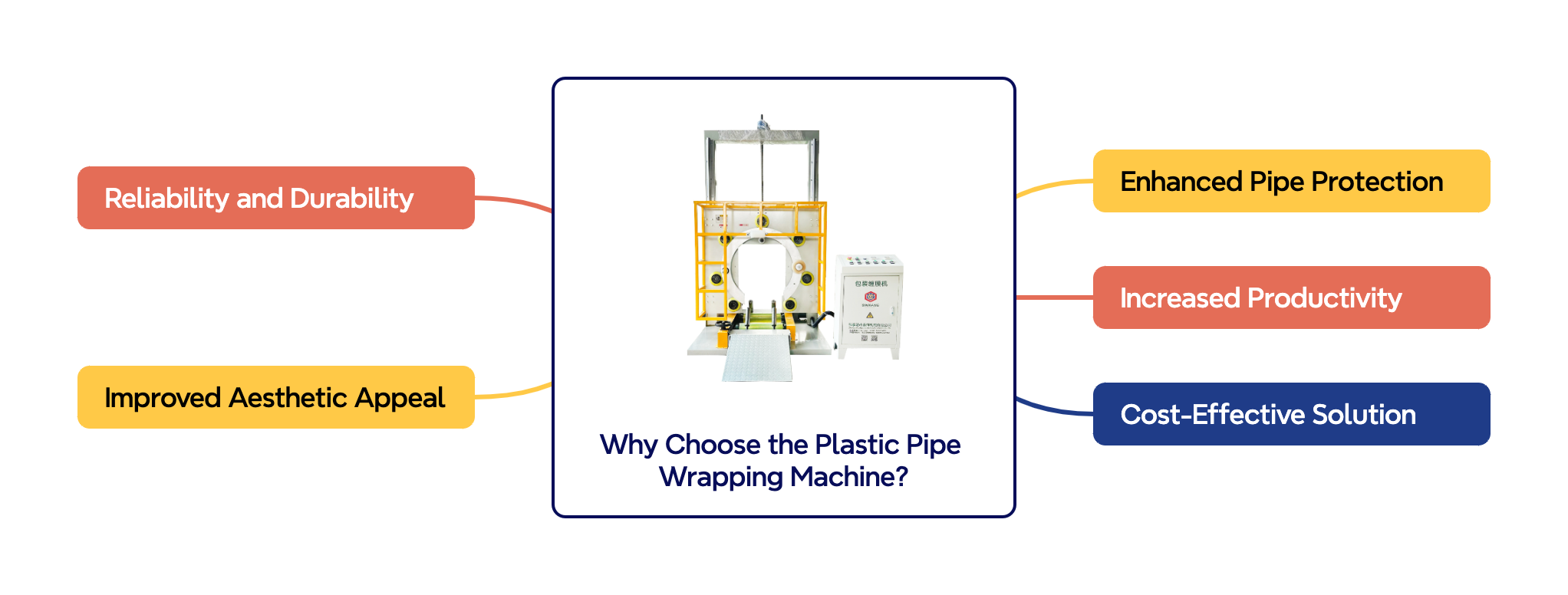

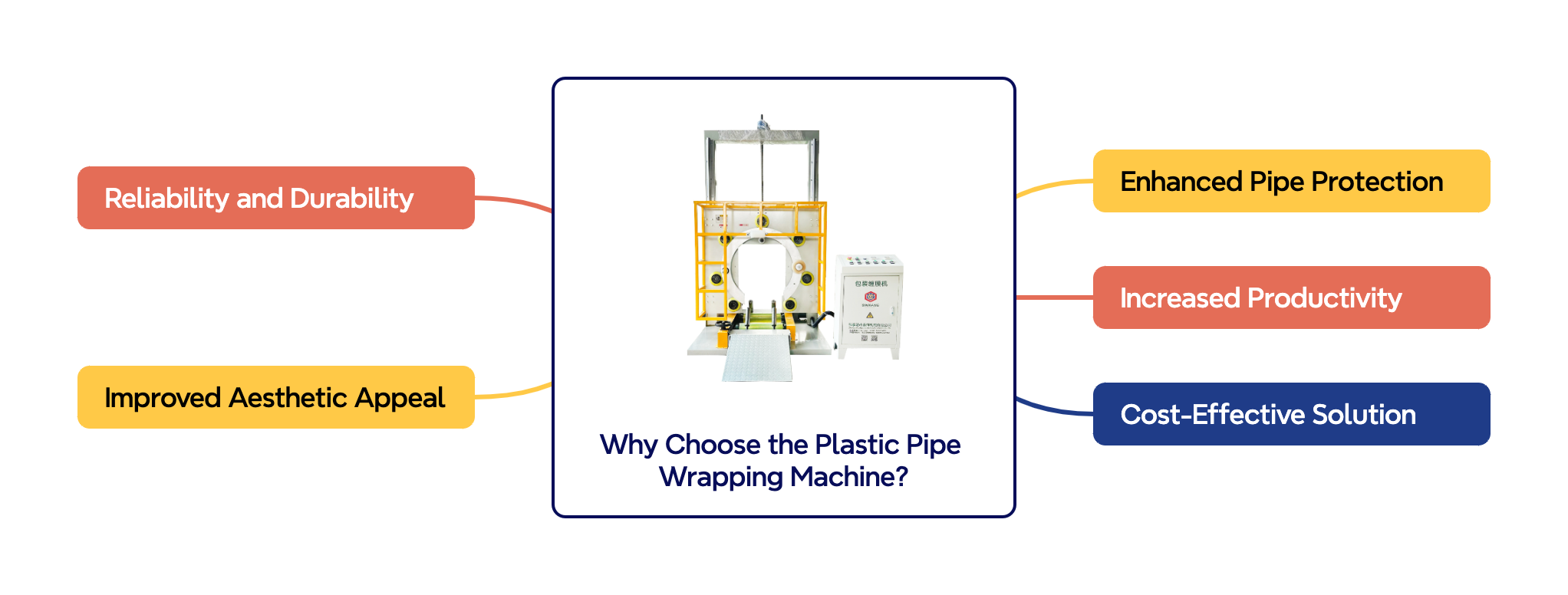

Why Choose the Plastic Pipe Wrapping Machine?

| 1 | Enhanced Pipe Protection |

| The machine ensures that pipes are fully protected from damage during transit and storage, reducing the risk of returns and customer complaints. |

| 2 | Increased Productivity |

| By automating the wrapping process, the machine significantly reduces labor costs and increases output, allowing manufacturers to meet growing demand. |

| 3 | Cost-Effective Solution |

| The precise control over film usage minimizes material waste, lowering packaging costs and supporting sustainable practices. |

| 4 | Improved Aesthetic Appeal |

| The uniform and professional wrapping enhances the visual appeal of the packaged pipes, boosting brand image and customer satisfaction. |

| 5 | Reliability and Durability |

| Built to withstand heavy-duty use, the machine offers unmatched reliability and a long service life, ensuring a high return on investment. |

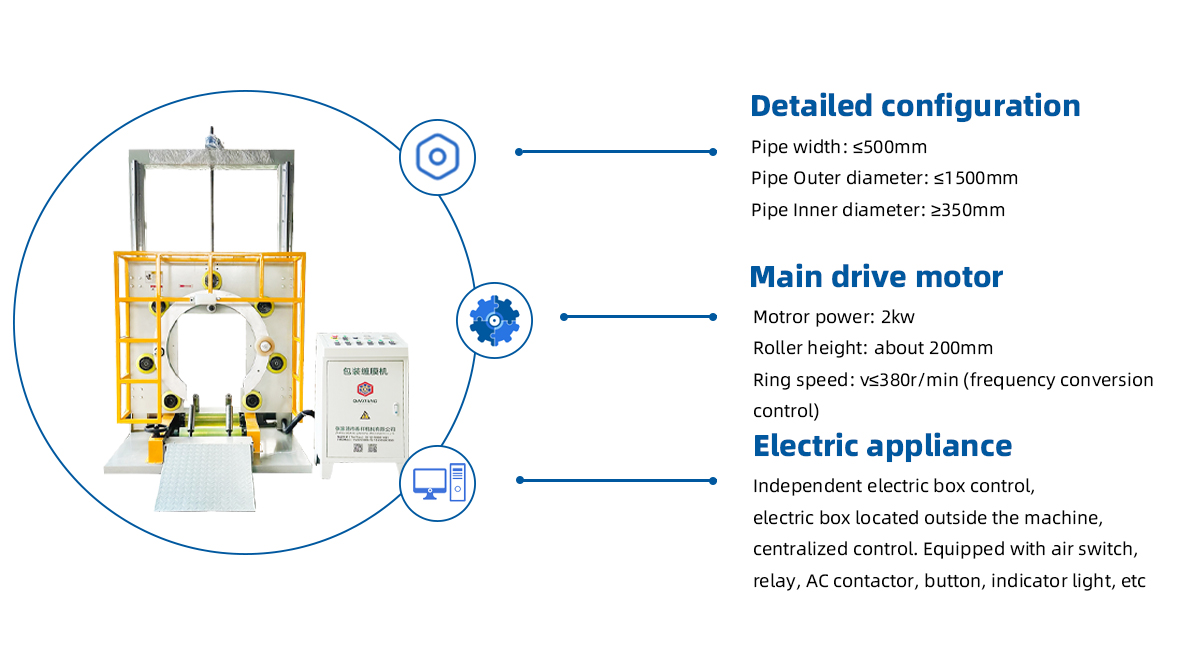

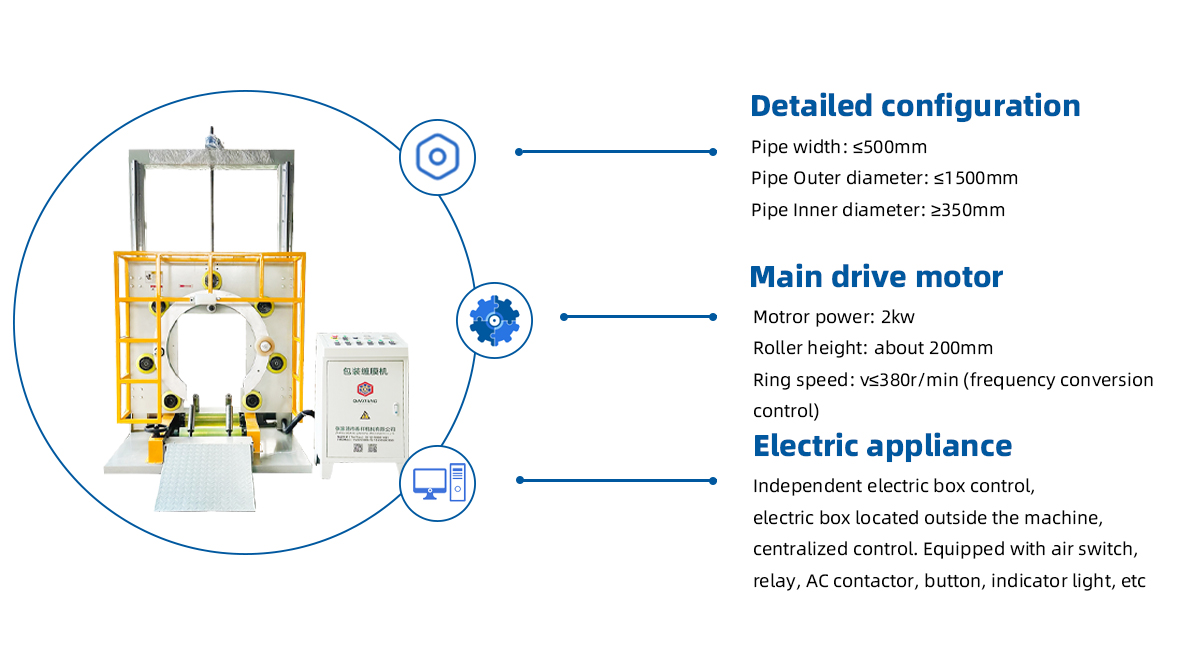

Technical Specifications

- Pipe Diameter Range: Compatible with pipes ranging from 20mm to 1200mm in diameter.

- Pipe Length: Adjustable to accommodate pipes of various lengths.

- Wrapping Speed: Adjustable speed settings for optimal performance.

- Wrapping Material: Compatible with stretch film, PE film, and shrink wrap.

- Power Supply: Available in standard and customized power configurations.

- Construction Material: High-grade steel and corrosion-resistant components.

The Plastic Pipe Wrapping Machine is the ultimate solution for manufacturers and suppliers looking to enhance the efficiency, quality, and reliability of their pipe packaging processes. With its advanced technology, robust design, and user-friendly features, it delivers unmatched performance and cost savings. Whether you're looking to protect your products, reduce operational costs, or improve customer satisfaction, the Plastic Pipe Wrapping Machine is the ideal choice for your needs.

Invest in the Plastic Pipe Wrapping Machine today and revolutionize your pipe packaging process with precision, efficiency, and reliability!

▏Product Advantage

Advantages of plastic pipe wrap packaging machine are mainly reflected in the following aspects:

| 1 | High efficiency and automation |

| The high degree of automation reduces the tedious manual operation and errors, and greatly improves the packaging efficiency. The equipment can work continuously and can pack several tubes per minute, significantly improving production efficiency. |

| 2 | Stable packaging quality |

|

Precise winding and sealing technology ensures that the tubing is not damaged during the packaging process, providing excellent protection. The packaging is tight and firm, which effectively prevents the wear and pollution of the pipe during transportation and storage. |

| 3 | Adaptable |

|

It can adapt to plastic pipes of different shapes, sizes and materials to meet diverse packaging needs. By adjusting parameters and replacing parts, you can quickly adapt to different specifications of pipe packaging. |

| 4 | Energy saving and environmental protection |

|

The equipment has low energy consumption, which is conducive to reducing production costs. The use of environmentally friendly materials and processes, in line with the requirements of green production, environmentally friendly. |

| 5 | Easy operation and maintenance |

|

The control panel design is intuitive and easy to understand, reducing the skill requirements of the operator. The compact structure of the equipment and easy parts replacement reduce maintenance costs and downtime. |

| 6 | Safe and reliable |

|

Safety protection device is provided to ensure the safety of operators. The operation of the equipment is stable and reliable, the failure rate is low, and the continuity of production is guaranteed. |

| 7 | Improve corporate image and product quality |

|

Clean, unified packaging to enhance the appearance of the product image, is conducive to enterprise brand promotion. Effective packaging protection reduces product damage during transportation, ensuring product quality and customer satisfaction. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping