▏Product Vedio

▏Product Introduction

▏Main Details

▏Product Photos

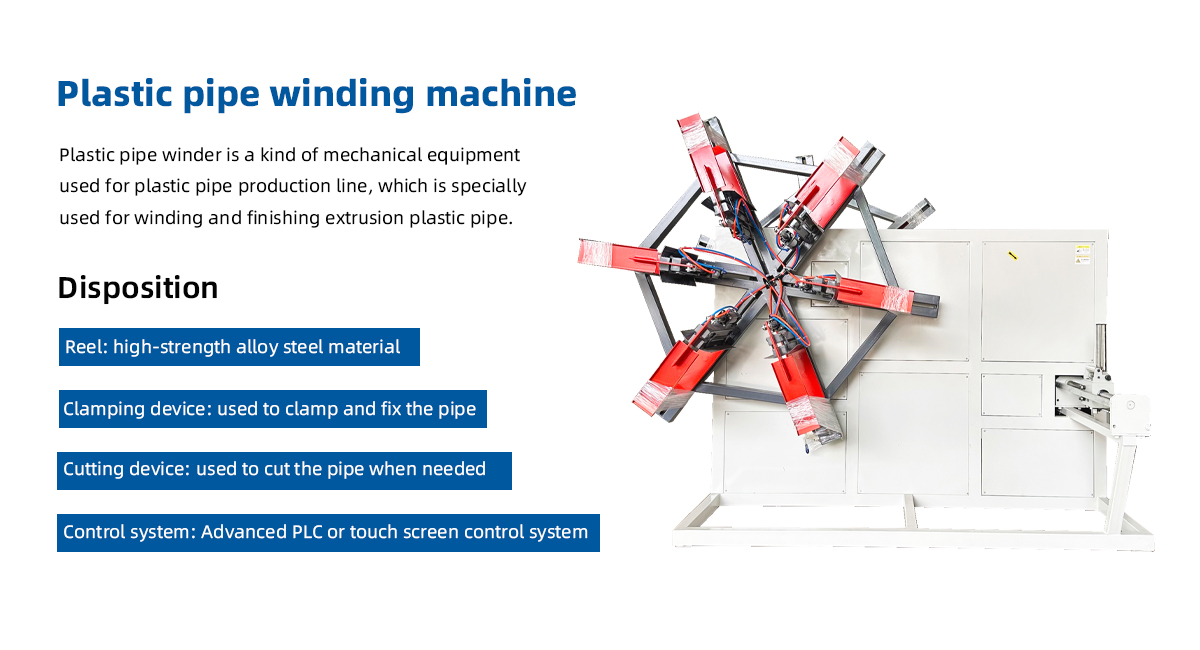

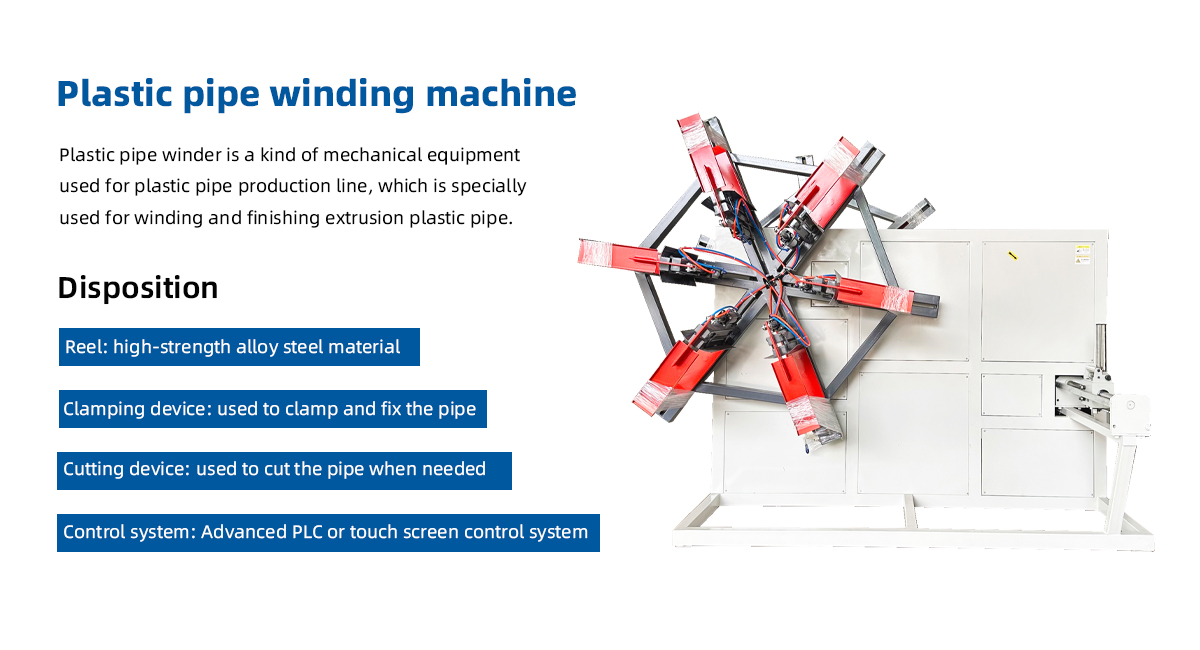

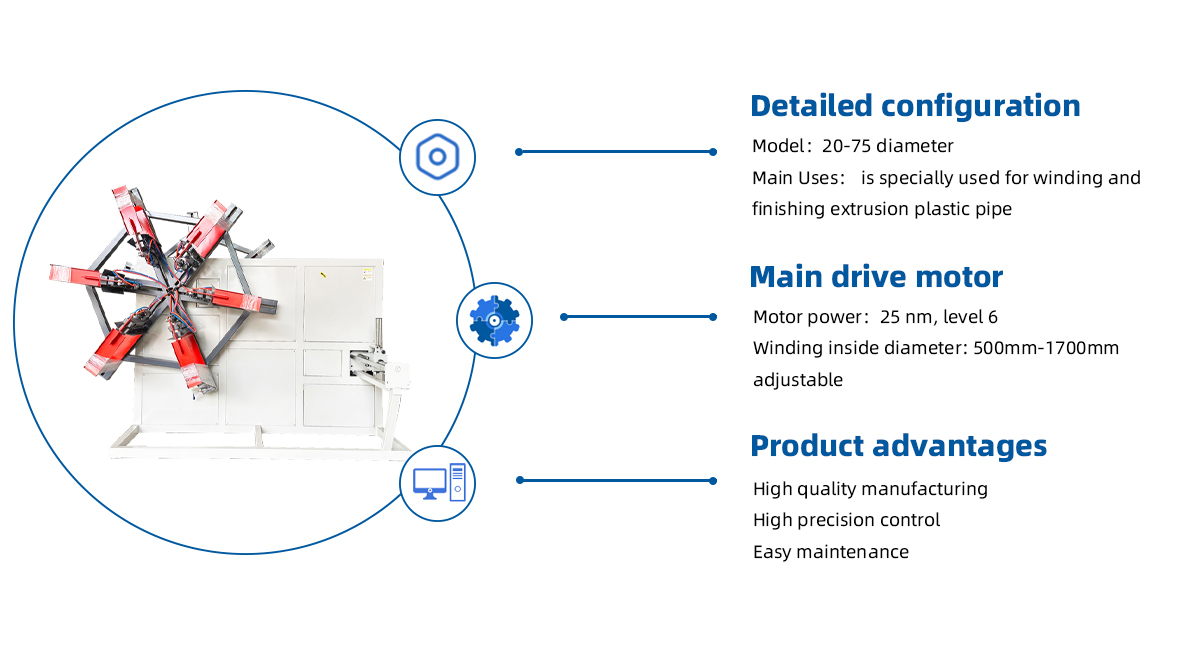

▏Plastic Pipe Winding Machine: The Ultimate Solution for Pipe Reinforcement and Protection

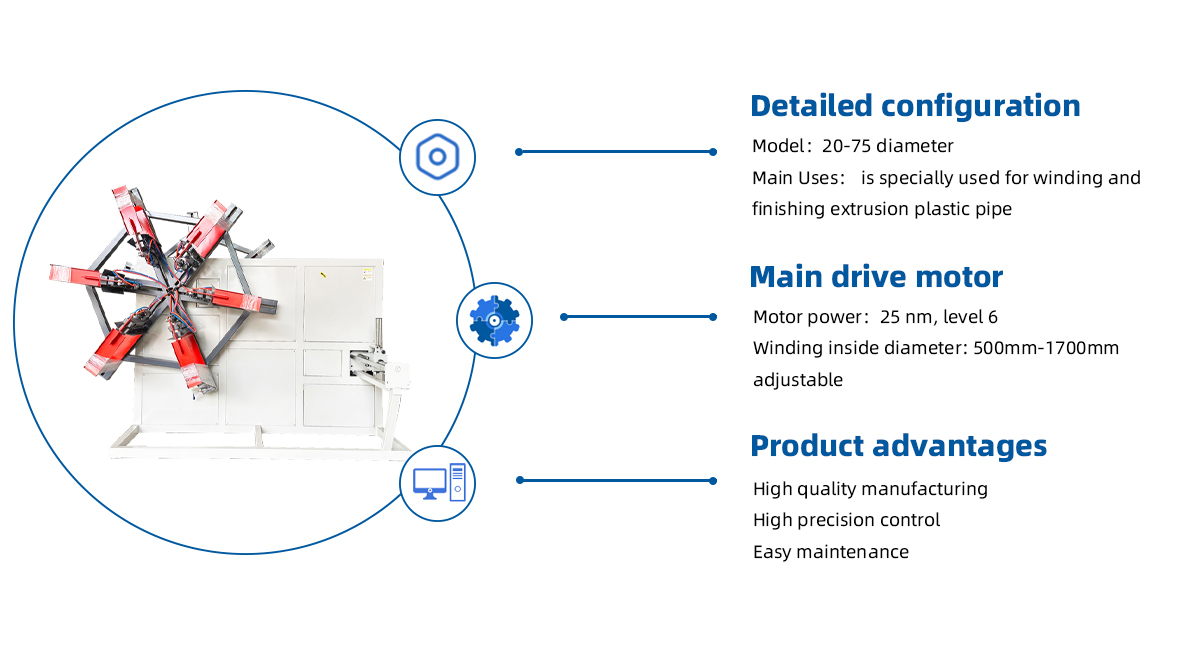

The Plastic Pipe Winding Machine is a state-of-the-art industrial equipment designed to revolutionize the production of reinforced plastic pipes. This advanced machine is engineered to apply high-strength reinforcement materials, such as fiberglass, carbon fiber, or thermoplastic tapes, onto plastic pipes in a precise and consistent manner. Ideal for manufacturers in the construction, plumbing, irrigation, and industrial sectors, the Plastic Pipe Winding Machine enhances pipe strength, durability, and performance, making it an indispensable tool for modern pipe production.

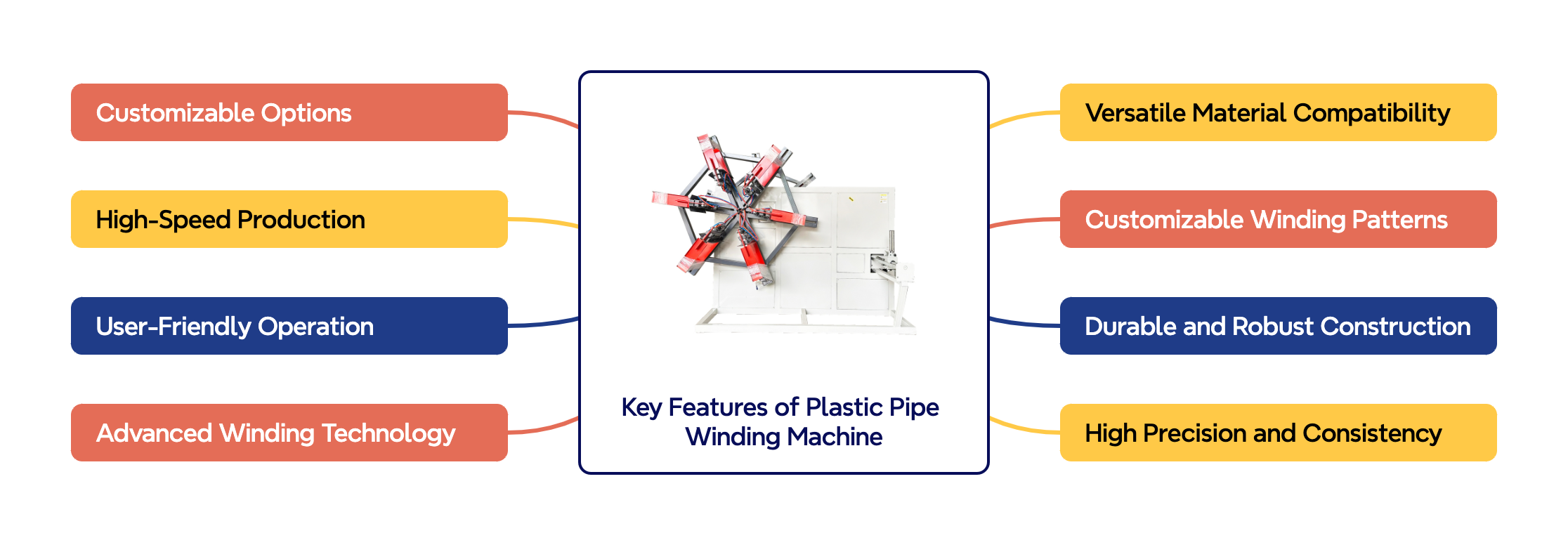

Key Features

| 1 | Advanced Winding Technology |

| The Plastic Pipe Winding Machine employs cutting-edge winding technology to apply reinforcement materials in a controlled spiral pattern. This ensures uniform distribution of strength and stress resistance along the entire length of the pipe. |

| 2 | High Precision and Consistency |

| Equipped with precision tension control and automated feeding systems, the machine delivers consistent winding results, eliminating gaps, overlaps, or weak spots in the reinforcement layer. |

| 3 | Versatile Material Compatibility |

| The machine is compatible with a wide range of reinforcement materials, including fiberglass, carbon fiber, aramid, and thermoplastic tapes, making it suitable for various pipe applications. |

| 4 | Customizable Winding Patterns |

| Operators can easily adjust winding angles, layer thickness, and material tension to meet specific pipe design requirements, ensuring optimal performance for different use cases. |

| 5 | Durable and Robust Construction |

| Built with high-quality materials and heavy-duty components, the Plastic Pipe Winding Machine is designed to withstand the demands of continuous industrial use. Its corrosion-resistant and wear-resistant construction ensures long-term reliability. |

| 6 | User-Friendly Operation |

| The machine features an intuitive control panel with a touchscreen interface, allowing operators to easily program and monitor winding parameters. Safety features, such as emergency stop buttons and protective guards, ensure safe and efficient operation. |

| 7 | High-Speed Production |

| Designed for high-volume manufacturing, the machine delivers fast and efficient winding speeds, significantly increasing productivity and reducing production lead times. |

| 8 | Customizable Options |

| The Plastic Pipe Winding Machine can be tailored to meet specific production needs, including different pipe diameters, lengths, and reinforcement requirements. |

Applications

The Plastic Pipe Winding Machine is a versatile solution for a wide range of industries and applications:

- Construction: Reinforcing PVC, HDPE, and PP pipes for building and infrastructure projects.

- Plumbing: Producing high-strength pipes for residential and commercial plumbing systems.

- Irrigation: Manufacturing durable pipes for agricultural irrigation and drainage systems.

- Industrial: Reinforcing pipes used in chemical processing, oil and gas, and water treatment facilities.

- Renewable Energy: Producing lightweight, high-strength pipes for wind turbine blades and solar panel supports.

Why Choose the Plastic Pipe Winding Machine?

| 1 | Enhanced Pipe Performance |

| The machine ensures that pipes are reinforced with optimal strength and durability, making them resistant to pressure, impact, and environmental factors. |

| 2 | Increased Productivity |

| By automating the winding process, the machine significantly reduces labor costs and increases production output, enabling manufacturers to meet growing demand. |

| 3 | Cost-Effective Solution |

| The precise control over material usage minimizes waste, lowering production costs and supporting sustainable manufacturing practices. |

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping