▏Product Introduction

▏Production Details

▏Product Photos

▏Plastic Raw Material Silo: The Ultimate Storage Solution for Plastic Manufacturing

The Plastic Raw Material Silo is a state-of-the-art storage system designed to meet the unique needs of the plastics manufacturing industry. Engineered for efficiency, durability, and reliability, this silo provides an optimal solution for storing and managing plastic raw materials such as pellets, granules, and powders. Whether you're producing injection-molded parts, extruded products, or blow-molded containers, the Plastic Raw Material Silo ensures consistent material quality, reduces waste, and enhances overall production efficiency.

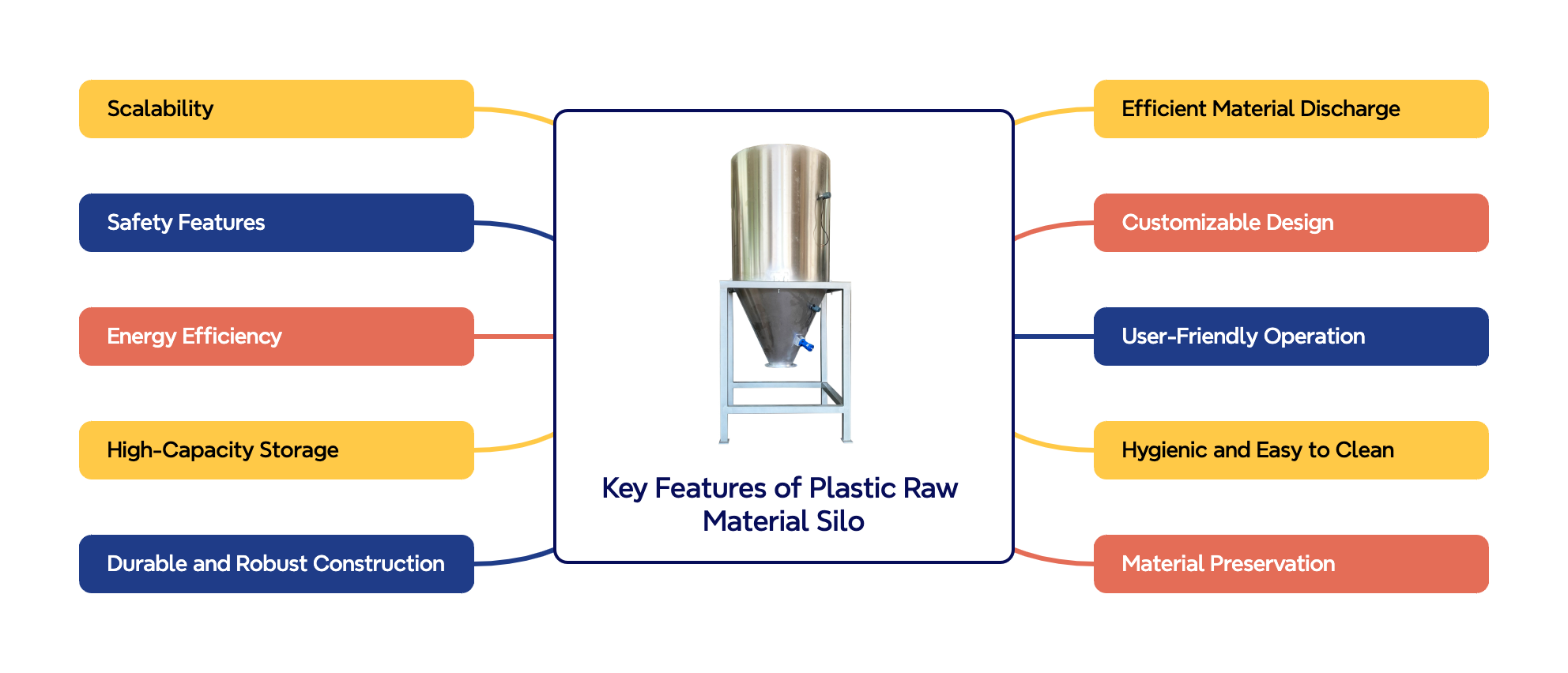

Key Features

| 1 | High-Capacity Storage |

| The silo is available in a range of sizes, from small units for limited spaces to large-capacity systems for high-volume production. It can store tons of plastic raw materials, ensuring a steady supply for continuous manufacturing processes. |

| 2 | Durable and Robust Construction |

| Built with high-quality materials such as stainless steel or carbon steel, the silo is resistant to corrosion, wear, and environmental factors. Its robust design ensures long-term durability and reliability. |

| 3 | Material Preservation |

| The silo is designed to protect plastic raw materials from moisture, dust, and contamination. Optional features such as airtight seals, desiccant breathers, and humidity control systems ensure material integrity and quality. |

| 4 | Efficient Material Discharge |

| Equipped with advanced discharge systems, such as cone bottoms, vibratory feeders, or screw conveyors, the silo ensures smooth and consistent material flow, preventing blockages and bridging. |

| 5 | Customizable Design |

| The silo can be tailored to meet specific production needs, including different sizes, shapes, and material compatibility. It can also be integrated with existing material handling systems, such as conveyors, blenders, or drying units. |

| 6 | User-Friendly Operation |

| The silo features an intuitive control panel that allows operators to monitor material levels, control discharge rates, and manage inventory. Automated systems can be added for enhanced efficiency and reduced manual labor. |

| 7 | Hygienic and Easy to Clean |

| With smooth surfaces and accessible interiors, the silo is easy to clean and maintain, ensuring compliance with hygiene standards in industries like food-grade plastics manufacturing. |

| 8 | Energy Efficiency |

| The silo is designed to minimize energy consumption during material storage and discharge, supporting sustainable manufacturing practices. |

| 9 | Safety Features |

| The silo includes safety mechanisms such as level sensors, pressure relief valves, and explosion-proof options to ensure safe operation in hazardous environments. |

| 10 | Scalability |

| The modular design of the silo allows for easy expansion, making it a future-proof investment for growing businesses. |

The Plastic Raw Material Silo is a versatile solution for a wide range of industries and applications:

- Injection Molding: Storing plastic pellets for the production of molded parts.

- Extrusion: Supplying raw materials for the manufacture of pipes, sheets, and profiles.

- Blow Molding: Storing granules for the production of bottles, containers, and other hollow products.

- 3D Printing: Managing plastic powders and filaments for additive manufacturing.

- Recycling: Storing recycled plastic materials for reuse in production processes.

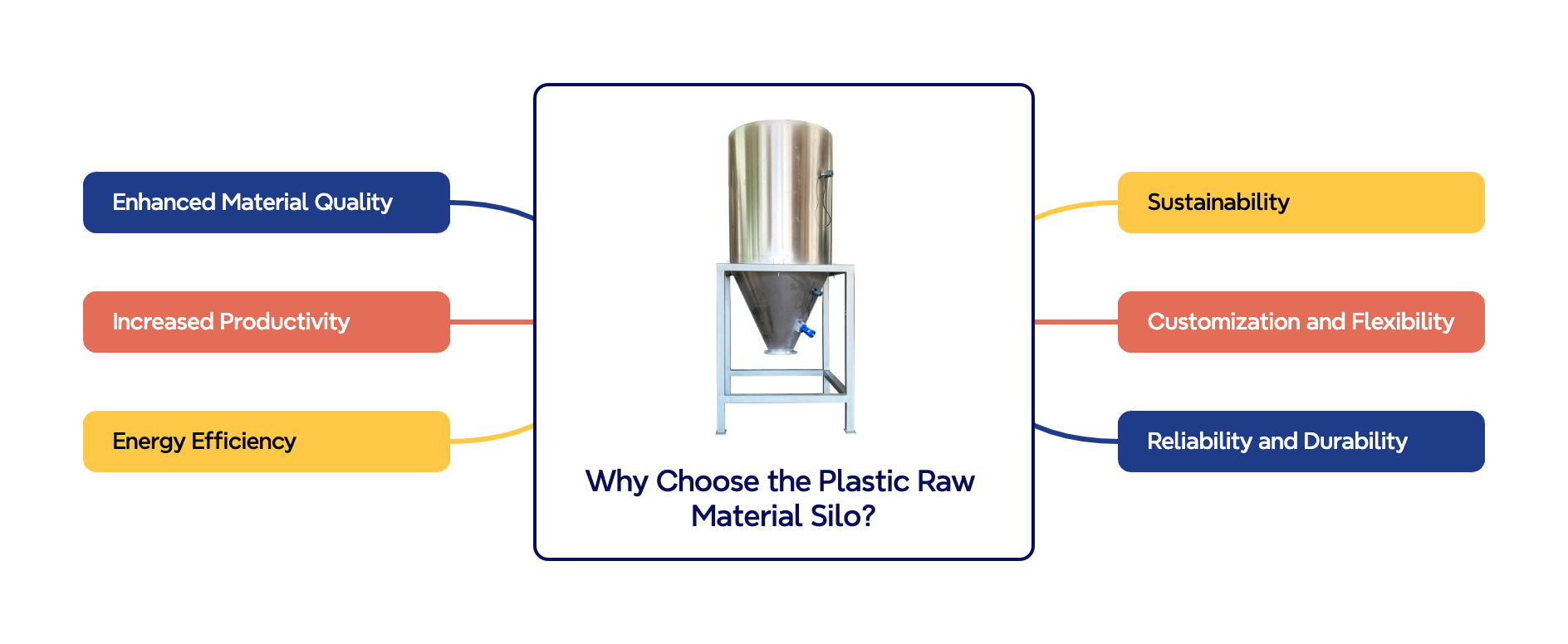

Why Choose the Plastic Raw Material Silo?

| 1 | Enhanced Material Quality |

| The silo ensures that plastic raw materials are stored in optimal conditions, preserving their quality and consistency. |

| 2 | Increased Productivity |

| By providing a steady supply of materials, the silo reduces downtime and enhances production efficiency. |

| 3 | Cost Savings |

| The efficient storage and discharge systems minimize material waste and reduce operational costs. |

| 4 | Reliability and Durability |

| Built to withstand heavy-duty use, the silo offers unmatched reliability and a long service life, ensuring a high return on investment. |

| 5 | Sustainability |

| By optimizing material usage and reducing waste, the silo supports environmentally friendly manufacturing practices. |

| 6 | Customization and Flexibility |

| The ability to tailor the silo to specific needs makes it suitable for diverse applications and industries. |

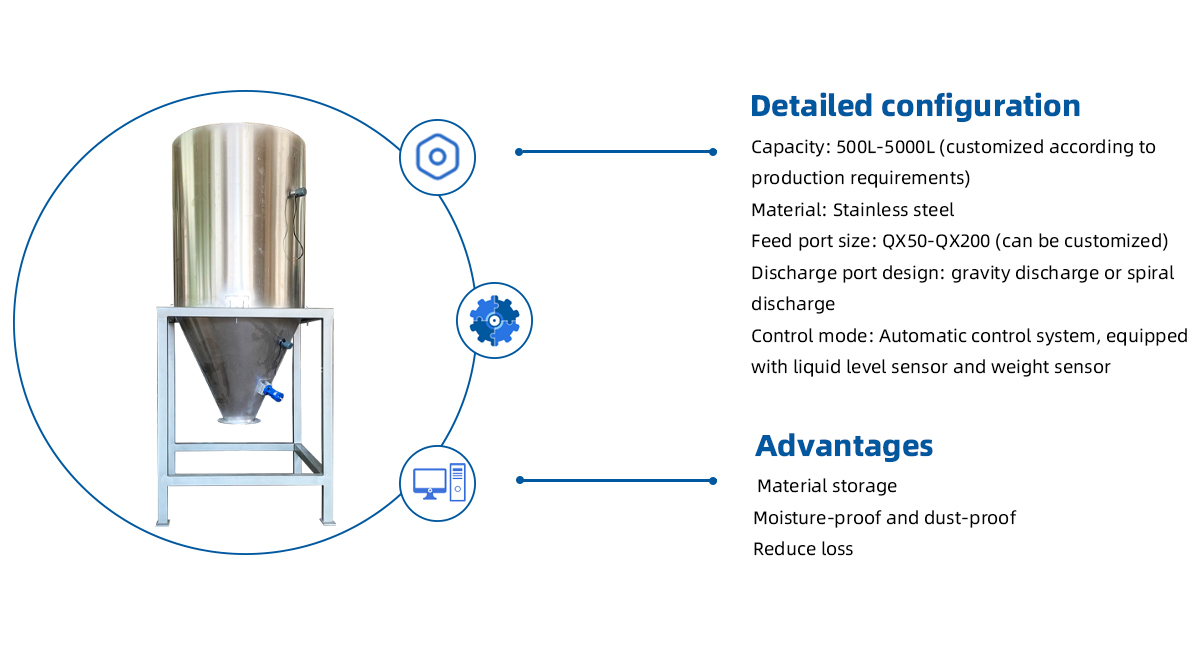

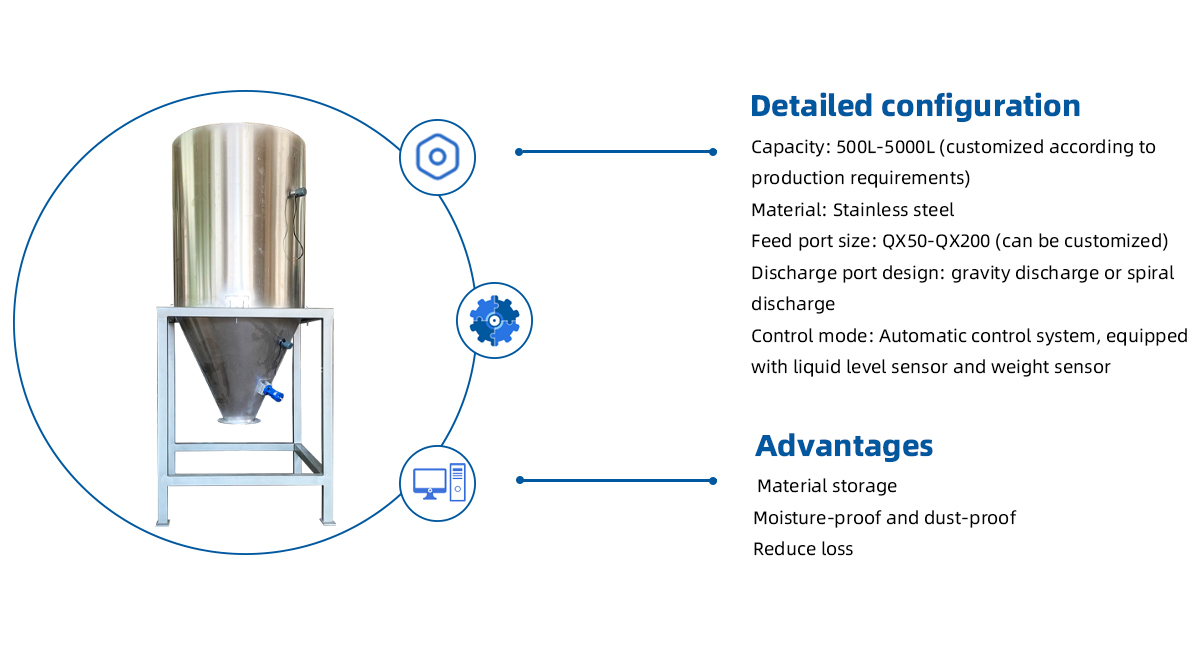

Technical Specifications

- Capacity: Available in various sizes, from 1 ton to 100+ tons.

- Material Compatibility: Suitable for plastic pellets, granules, powders, and flakes.

- Construction Material: High-grade stainless steel or carbon steel.

- Discharge Systems: Cone bottoms, vibratory feeders, screw conveyors, or pneumatic systems.

- Optional Features: Humidity control, level sensors, and explosion-proof designs.

The Plastic Raw Material Silo is the ultimate storage solution for plastic manufacturers seeking to optimize their material handling processes. With its advanced technology, robust design, and user-friendly features, it delivers unmatched efficiency, reliability, and performance. Whether you're producing injection-molded parts, extruded profiles, or blow-molded containers, the Plastic Raw Material Silo is the ideal choice for ensuring consistent material quality and enhancing production efficiency.

Invest in the Plastic Raw Material Silo today and take your plastic manufacturing process to the next level with superior storage technology and unmatched quality!

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping