The global plastics industry is built on precision, efficiency, and the ability to transform raw materials into diverse, functional products. At the heart of this transformation lies plastic processing machinery—a broad category of equipment responsible for converting polymer resins into everything from packaging films to automotive parts and construction pipes. Whether you’re producing lightweight components or heavy-duty profiles, choosing the right plastic machine is key to scaling production, maintaining consistency, and achieving cost-effectiveness.

At Zhangjiagang Qinxiang Machinery Co., Ltd., we understand the dynamic needs of modern manufacturers. With years of experience in designing and supplying specialized plastic processing equipment, we provide reliable, customizable solutions that help our clients stay ahead in an evolving market.

What Are Primary Plastic Processing Machines?

Plastic processing machinery encompasses several types of core production systems. Each type handles the transformation of polymer pellets or powders into a specific shape or product, using controlled heat, pressure, and forming techniques. The main categories include:

1. Extrusion Machines

Used for continuous production of pipes, profiles, and sheets, extrusion involves melting plastic and pushing it through a die. It’s one of the most versatile and widely used plastic forming techniques.

2. Injection Molding Machines

Ideal for high-volume part manufacturing, these machines inject molten plastic into a mold to create precise, repeatable products. Injection molding is especially common in consumer goods, automotive components, and packaging industries.

3. Blow Molding Machines

Specialized in hollow plastic products like bottles, drums, and containers, blow molding uses compressed air to shape molten plastic inside a mold cavity.

4. Thermoforming Machines

These machines heat plastic sheets until pliable, then use vacuum or pressure to mold them over a form. It’s widely used in the food packaging and medical industries.

5. Rotational Molding Machines

Used for large hollow products such as water tanks, playground equipment, and industrial bins. It involves rotating a mold filled with powder inside a heated oven until the material coats the interior.

Each machine serves a unique purpose and is optimized for specific product geometries, production speeds, and material types.

How Do Extruders Work?

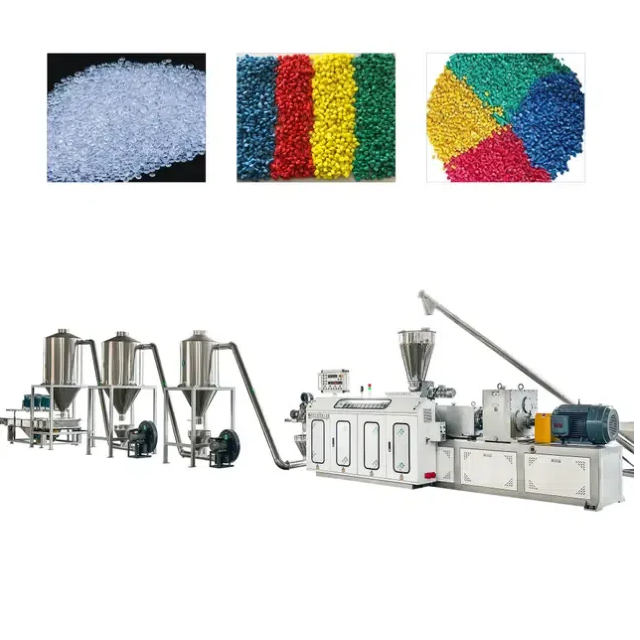

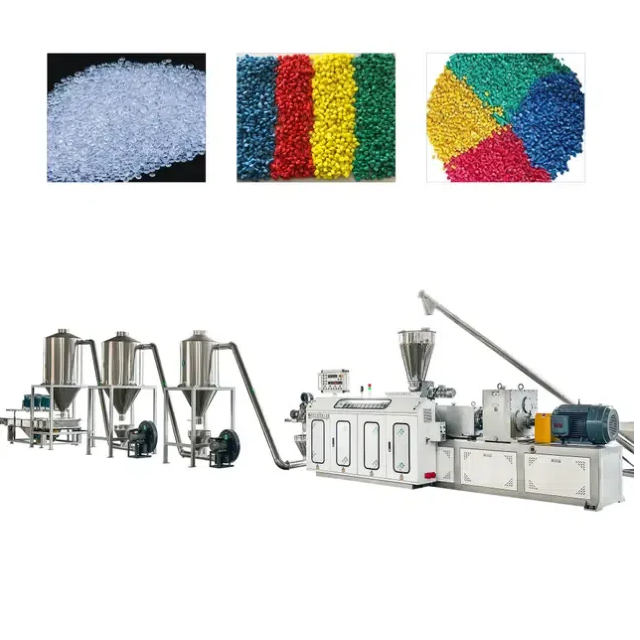

One of the most fundamental machines in plastic processing is the extruder, especially for continuous-form products like pipes, sheets, or profiles. At Zhangjiagang Qinxiang Machinery Co., Ltd., we specialize in building extrusion systems tailored for PVC, PE, PP, and other thermoplastics.

An extruder operates by feeding polymer pellets into a heated barrel, where a single-screw or twin-screw mechanism melts and homogenizes the material. The molten plastic is then forced through a shaped die, which determines the final geometry—such as the diameter of a pipe or the width of a sheet.

Additional components such as vacuum calibrators, cooling tanks, and traction devices ensure that the product maintains dimensional accuracy and surface finish as it cools and solidifies.

For instance, a plastic sheet making machine will be configured with wide flat dies and cooling rollers to form rigid or semi-flexible plastic sheets for packaging, signage, or construction. Similarly, a plastic profile making machine is designed with multi-cavity dies to produce window frames, trim boards, or cable ducts.

Inline equipment—like additive feeders, recycling granulators, and cutting systems—can be added to enhance functionality and reduce waste, providing a highly efficient, closed-loop system.

What Happens in Injection and Blow Molding?

While extrusion is ideal for continuous products, injection molding is the go-to solution for complex, three-dimensional parts with tight tolerances. The process begins by melting plastic in a barrel and injecting it under high pressure into a metal mold cavity. Once cooled, the mold opens, and the part is ejected.

Modern injection molding machines are available in three main configurations:

Hydraulic machines, known for durability and high clamping force

Electric machines, offering energy savings, faster cycles, and cleaner operation

Hybrid machines, combining the strengths of both

These machines are used to produce everything from toothbrushes to automotive dashboards, using materials like ABS, PS, and PA.

On the other hand, blow molding machines specialize in producing hollow forms. In this process, a preform or parison (a hot tube of plastic) is placed in a mold, and air is blown into it, expanding the plastic to fit the mold’s shape. There are various types of blow molding—extrusion, injection stretch, and injection blow molding—each suited for specific container shapes and production needs.

Plastic pipe making machines and plastic profile making machines often include blow molding or extrusion capabilities, depending on the final application and geometry of the product.

What Are Thermoforming and Rotational Machines?

Thermoforming is another key process, used extensively for packaging trays, containers, and disposable medical products. A plastic sheet making machine first produces the sheet, which is then heated in the thermoformer until it softens. The sheet is then pulled over or into a mold using vacuum pressure (vacuum forming) or a combination of vacuum and mechanical pressure (pressure forming).

Thermoforming is especially cost-effective for medium-to-large production runs where part geometries are relatively simple but speed and clarity are essential.

Meanwhile, rotational molding (or rotomolding) is employed for very large, hollow items made from thermoplastic powders, like polyethylene. A pre-measured quantity of powder is loaded into a mold, which is then rotated biaxially inside an oven. The heat melts the powder and evenly coats the interior mold surface. Once cooled, the mold is opened, and the part is removed.

This low-pressure process is ideal for making durable, seamless products with uniform wall thickness, such as playground slides or septic tanks.

What Auxiliary Equipment Supports Processing?

No plastic machine operates in isolation. To ensure product quality, reduce energy consumption, and maintain productivity, a wide range of auxiliary equipment is used in tandem with the core processing systems.

Dryers: Remove moisture from raw materials to prevent bubbles and degradation during melting.

Chillers: Control cooling rates for extrusion lines or injection molds, essential for dimensional accuracy.

Mixers and blenders: Ensure even distribution of pigments, additives, or recycled material.

Conveyors and feeders: Automate raw material transport, enhancing throughput and reducing labor needs.

Integration of these units with processing machinery leads to more streamlined operations, higher output consistency, and better material utilization. At Zhangjiagang Qinxiang Machinery Co., Ltd., our complete system offerings include all necessary auxiliary components, designed for seamless coordination and long-term reliability.

Conclusion

The type of plastic processing machinery you choose directly impacts your product quality, manufacturing speed, energy efficiency, and market competitiveness. Whether you require a high-output plastic pipe making machine, a precision injection molding system, or a versatile plastic sheet making machine, investing in the right equipment from the start pays off in reduced waste, faster ROI, and greater customer satisfaction.

At Zhangjiagang Qinxiang Machinery Co., Ltd., we are committed to providing cutting-edge plastic machines tailored to your production needs. Our machines combine intelligent design with durable engineering and are supported by a knowledgeable team ready to assist from consultation to after-sales service.

Contact us today to discuss how our plastic processing machinery solutions can elevate your production capabilities and help you succeed in a competitive market.