▏Product Vedio

▏Plastic Drying Mixer | Plastic Granule Dryer Machine for Injection Molding and Extrusion

In the modern plastic processing industry, drying plastic raw materials is a critical step that ensures high product quality and efficient production. Our Plastic Drying Mixer is a high-performance solution designed for drying and mixing plastic granules and pellets before they are fed into injection molding machines or extruders. This system is especially ideal for applications requiring a Plastic Granule Dryer Machine, Plastic Material Dryer, or Drying Hopper for Plastic Industry.

Whether you're operating in automotive, packaging, construction, or consumer goods sectors, our Plastic dryer for injection molding raw materials guarantees consistent drying, energy efficiency, and ease of operation.

▏Main Features

Integrated Drying and Mixing: Simultaneous drying and homogenization of plastic granules.

High-Temperature Resistant Hopper: Built with SUS304 stainless steel, durable and corrosion-resistant.

Digital Temperature Control: Accurate PID temperature controller with LED display.

High Efficiency Heater: Rapid heating system reduces energy consumption and startup time.

Safety Protection: Overheat protection, motor overload protection, and automatic shutdown features.

Easy Maintenance: Modular design allows quick access for cleaning and servicing.

▏Product Photo

▏Applications

Our Plastic Drying Mixer is widely used in:

| Industry | Application |

| Injection Molding | Drying ABS, PC, PA, PET, PMMA raw materials |

| Extrusion | Drying PE, PP, PVC pellets before extrusion |

| Blow Molding | Ensures low moisture content in HDPE and LDPE materials |

| Recycling | Prepares cleaned plastic flakes for reprocessing |

| Medical | Cleanroom-compatible designs for high purity materials |

▏Advantages

Consistent Drying Performance: Reduces moisture levels to below 0.02%.

Energy Efficient Design: Saves up to 30% power compared to conventional dryers.

Compact Footprint: Ideal for space-constrained production areas.

Versatility: Compatible with a wide range of plastic materials and processing lines.

Reliable for High-Output Operations: Suitable for 24/7 industrial use.

▏Technical Configuration

| Model | Capacity (kg/h) | Heater Power (kW) | Hopper Volume (L) | Dimensions (mm) |

| PDM-25 | 25 | 3 | 50 | 600x450x900 |

| PDM-50 | 50 | 6 | 100 | 700x500x1100 |

| PDM-100 | 100 | 9 | 200 | 850x650x1350 |

| PDM-200 | 200 | 15 | 400 | 1000x800x1500 |

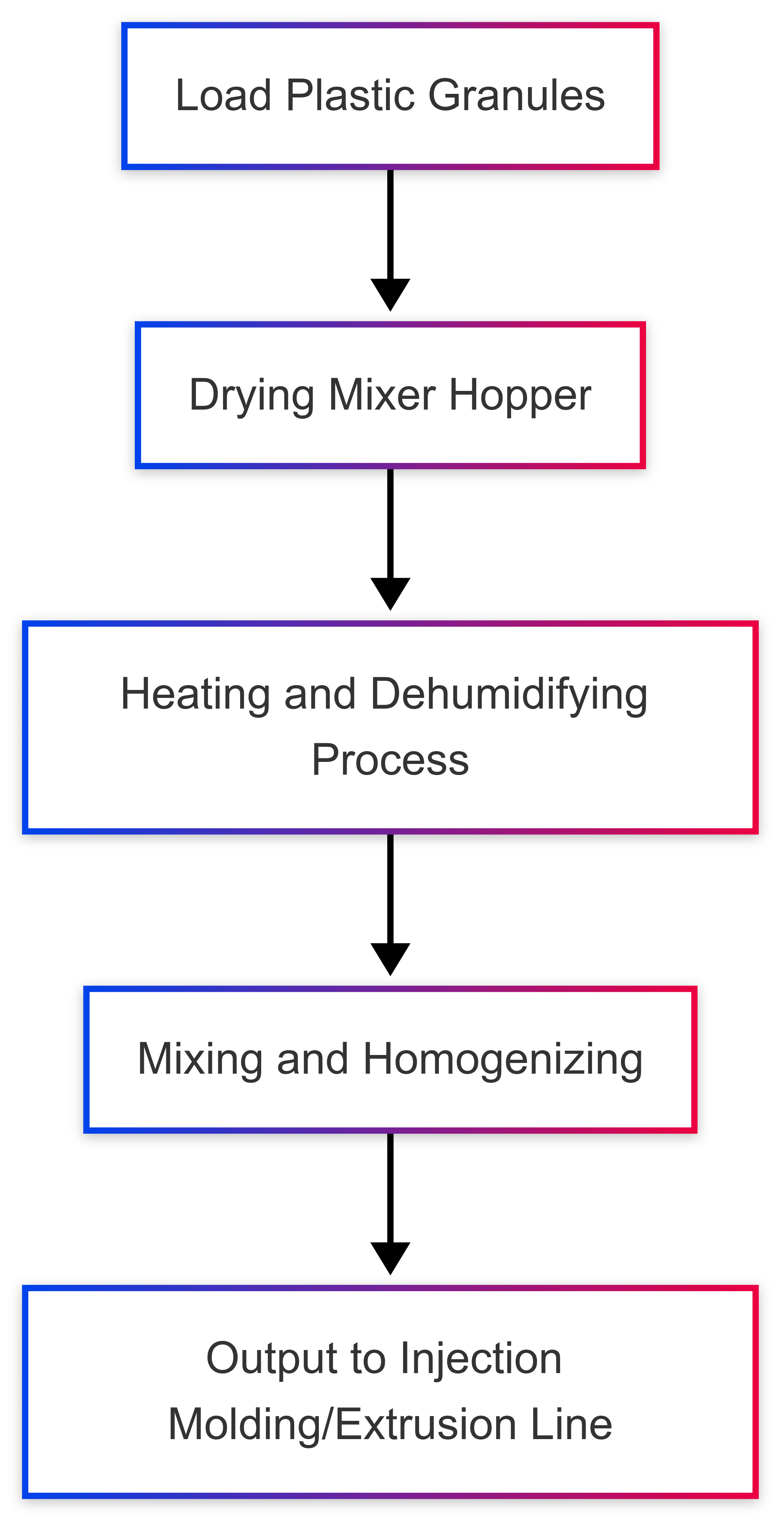

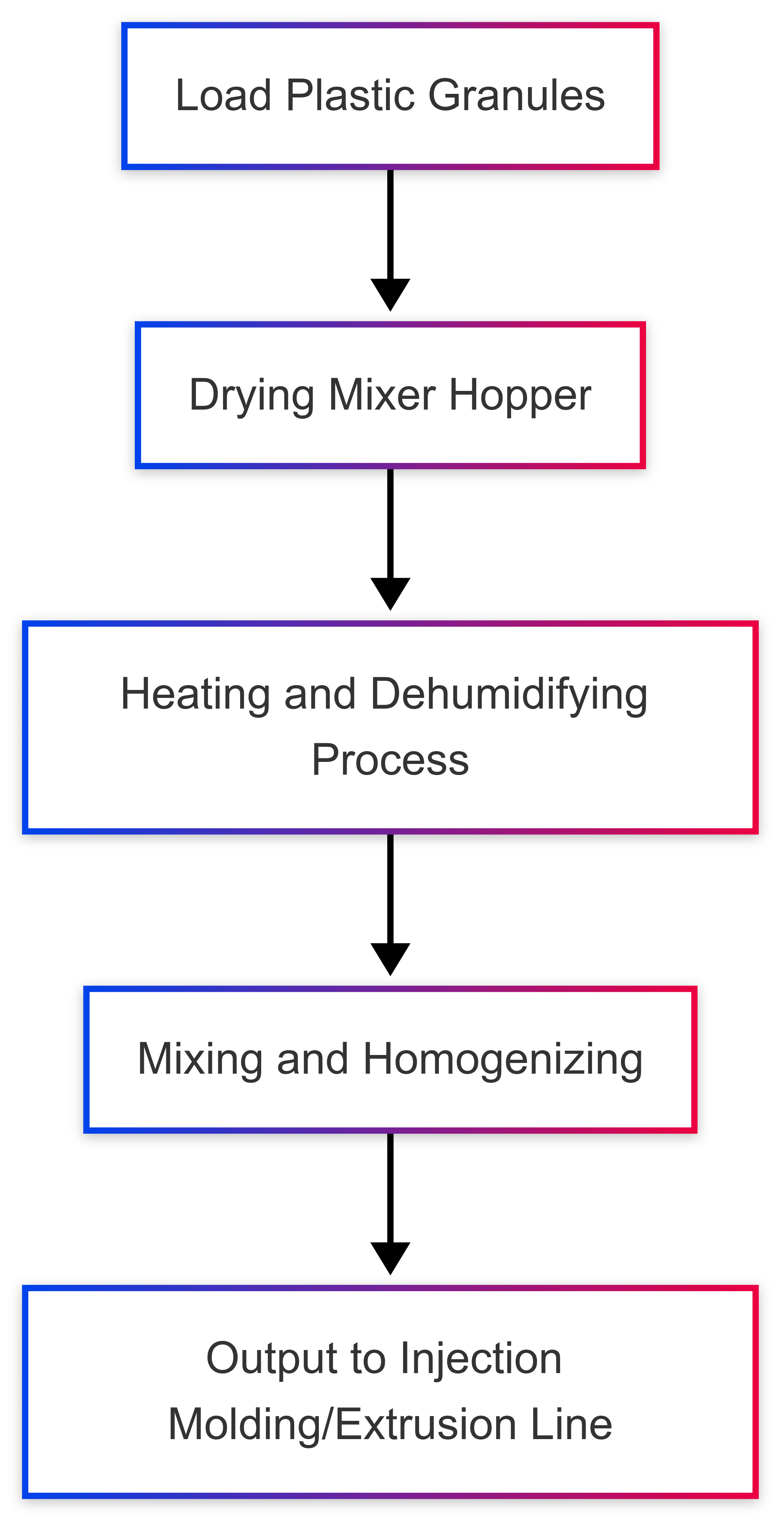

▏Production Workflow

Here is a typical process flow of using the Plastic Drying Mixer:

▏Customer Case Studies

Case Study 1: Automotive Components Manufacturer in Germany

Problem: High reject rate due to moisture in nylon (PA) granules.

Solution: Installed PDM-100 model.

Result: Moisture reduced to <0.02%, reject rate dropped by 40%, production output increased.

Case Study 2: PET Bottle Preform Factory in Vietnam

Problem: Inconsistent PET drying using traditional hot air dryers.

Solution: Upgraded to PDM-200.

Result: Stable moisture level achieved; improved product clarity and strength.

Case Study 3: Recycling Plant in Mexico

Problem: Recycled flakes absorbing humidity after washing.

Solution: Integrated PDM-50 to pre-dry materials.

Result: Enhanced pellet quality and extrusion performance.

▏Why Choose Us?

Over 20 Years of Manufacturing Experience in plastic processing equipment.

Global Service Network with installation, training, and maintenance support.

Customizable Solutions tailored to your factory layout and material types.

CE & ISO Certified machinery ensuring safety and compliance.

Fast Delivery Time and reliable after-sales service.

▏Get a Quote Today

Improve your plastic product quality and streamline your drying process. Contact us for a customized solution with our high-efficiency Plastic Drying Mixer!

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping