▏Product Introduction

▏Technical Parameters

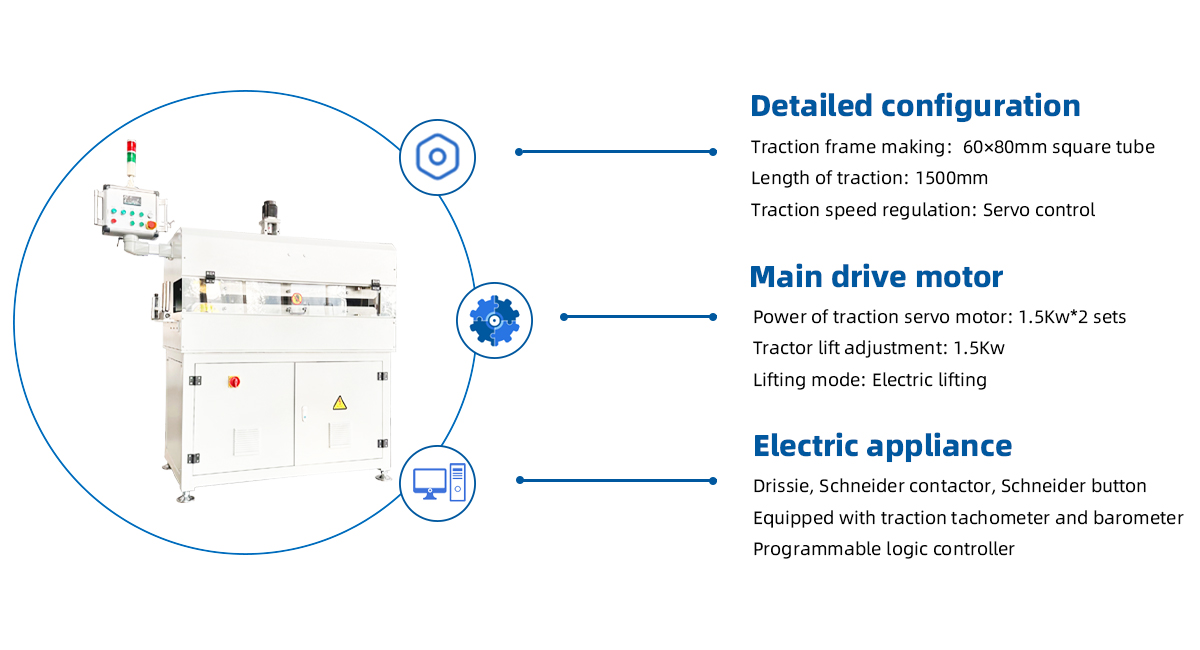

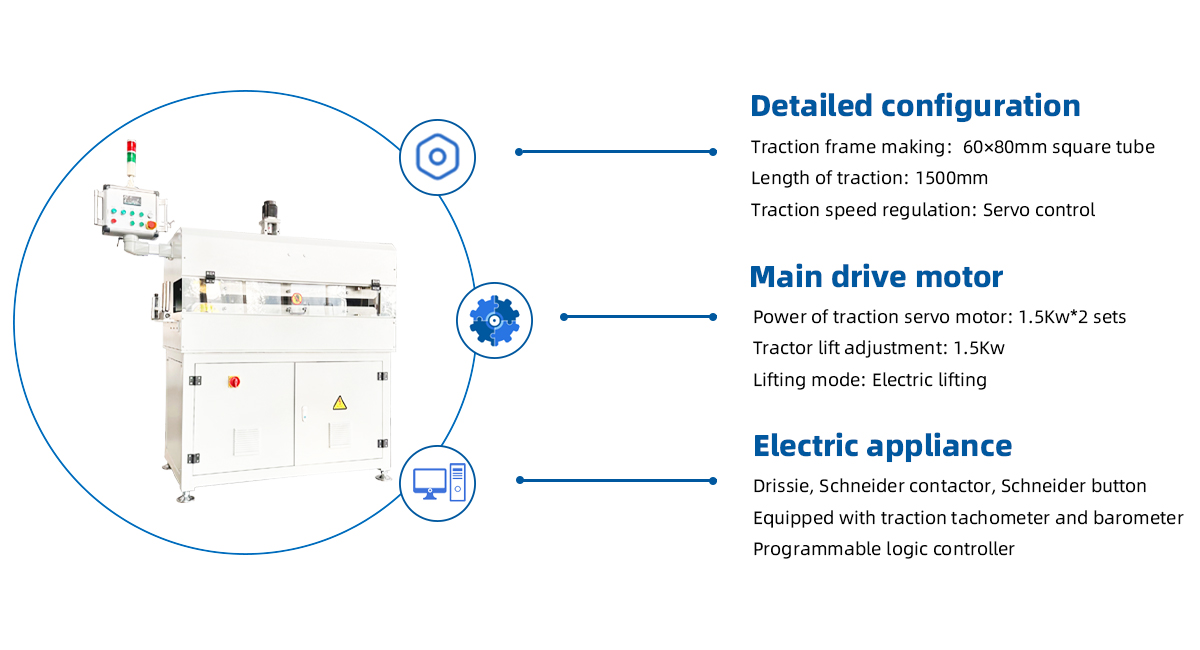

Traction frame making |

60×80mm square tube |

| Length of traction |

1500mm |

| Traction speed regulation |

Servo control |

Power of traction servo motor |

1.5Kw*2 sets |

| Tractor lift adjustment |

1.5Kw |

| Lifting mode |

Electric lifting |

▏Main Details

▏Product Photos

High precision positioning and traction

Strong stability

Efficient energy utilization

Precise traction control

Strong adaptability

High durability

Easy and intuitive operation

High degree of intelligence

Easy maintenance

Environmental protection and energy saving

▏Servo Belt Haul-Off Machine: Precision and Efficiency for Continuous Production Lines

The Servo Belt Haul-Off Machine is a cutting-edge industrial solution designed to revolutionize material handling in continuous production processes. Combining advanced servo motor technology with a robust belt-driven system, this machine delivers unparalleled precision, stability, and adaptability for industries such as plastic extrusion, rubber manufacturing, cable production, and sheet processing. Whether you’re handling delicate films, rigid profiles, or high-speed extrusion lines, the Servo Belt Haul-Off Machine ensures optimal tension control, minimal material deformation, and seamless integration into your production workflow.

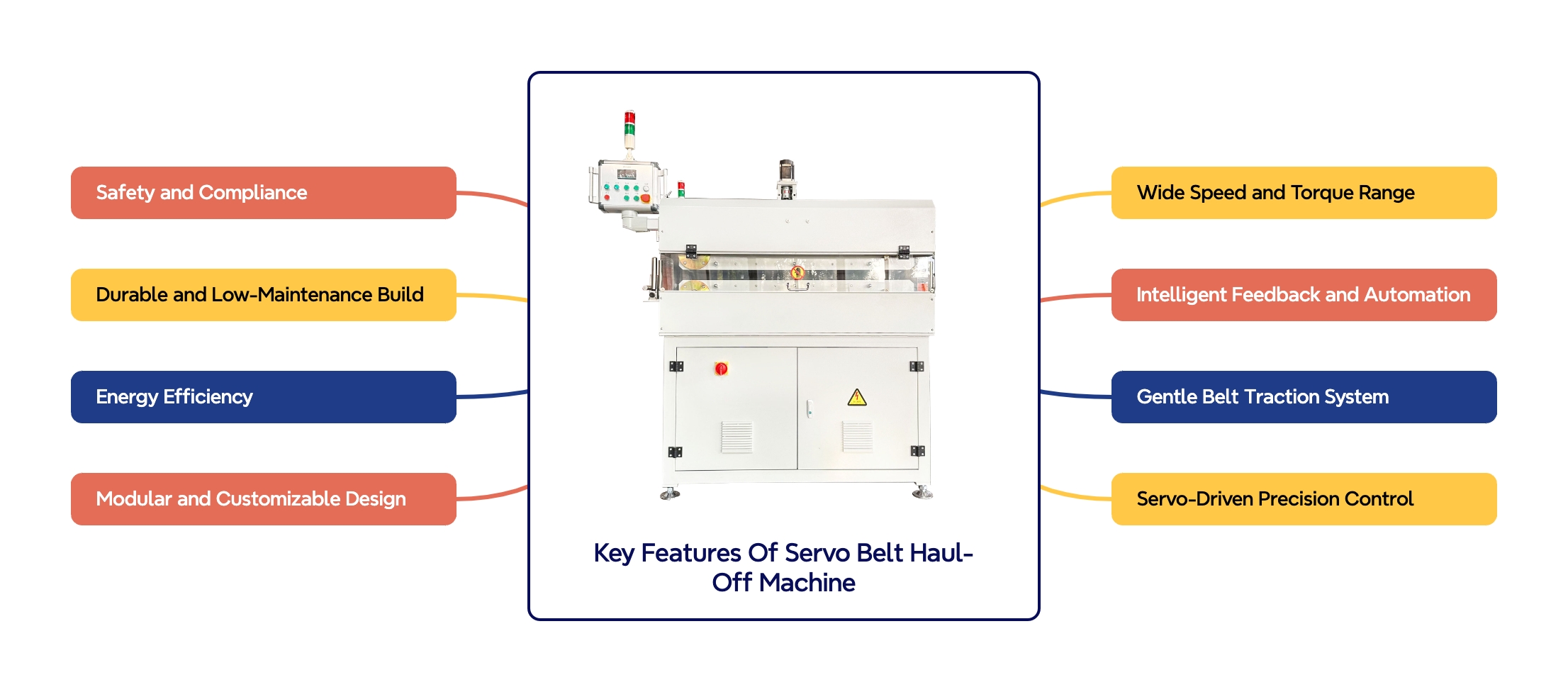

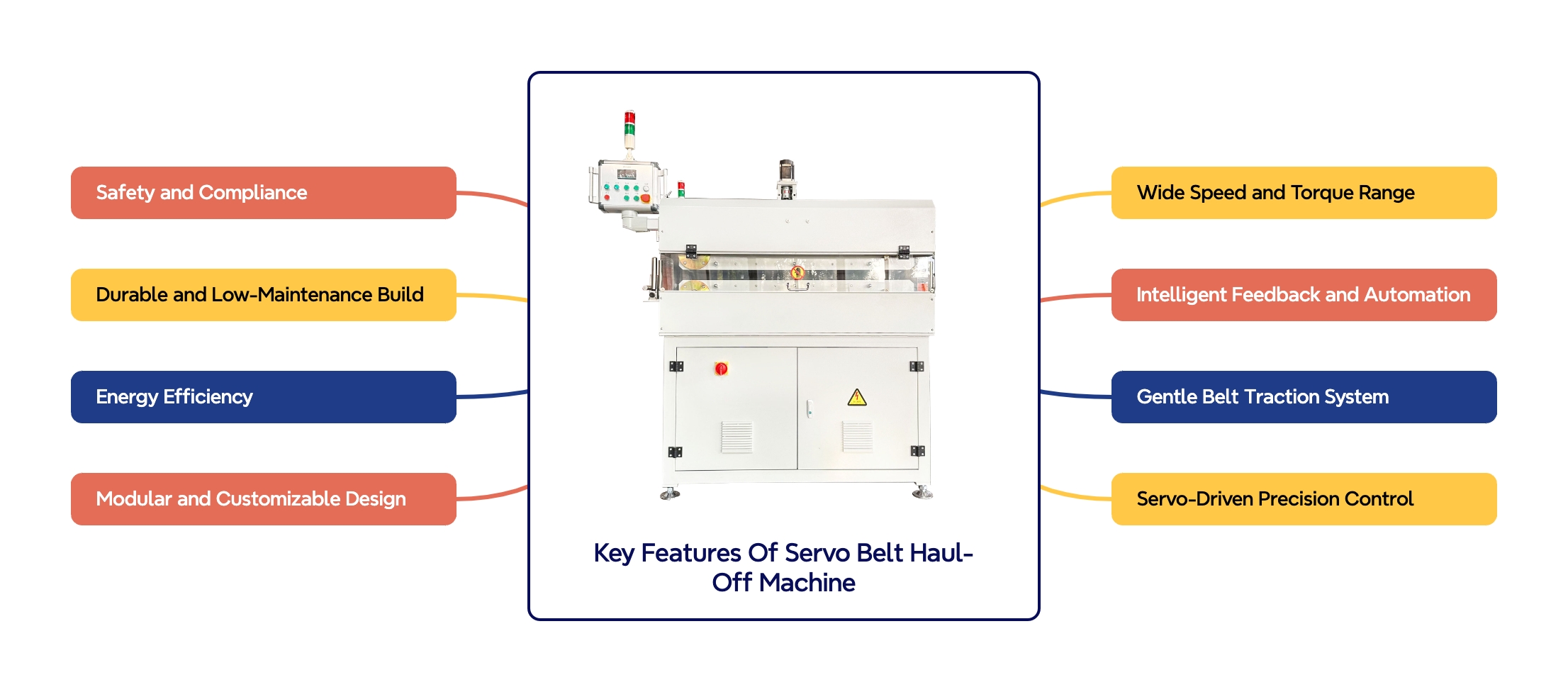

Key Features

| 1 |

Servo-Driven Precision Control |

|

Equipped with a high-performance servo motor, the machine offers **real-time speed and tension adjustments** with micron-level accuracy. This ensures consistent material pull-off rates, eliminating stretching, slippage, or distortion even at high production speeds. |

| 2 |

Gentle Belt Traction System |

|

Unlike traditional roller-based haul-off systems, the **belt-driven design** provides uniform contact pressure across the material surface. This is ideal for sensitive products like thin films, optical cables, or soft rubber profiles, preventing surface marks or damage. |

| 3 |

Wide Speed and Torque Range |

|

The machine supports variable speed control (from 0.1 to 100+ meters per minute) and high torque output, adapting effortlessly to diverse production requirements—from ultra-slow precision tasks to high-throughput operations. |

| 4 |

Intelligent Feedback and Automation |

|

Integrated with PLC and HMI interfaces, the system allows operators to preset parameters, monitor real-time data (tension, speed, length), and automate workflows. Compatibility with Industry 4.0 protocols enables remote diagnostics and smart factory integration. |

| 5 |

Modular and Customizable Design |

|

Adjustable Belt Width and Length: Tailored to handle materials from 10mm to 2000mm in width. Multi-Layer Traction: Optional dual or triple belt configurations for heavy-duty applications. Material Compatibility: Suitable for plastics (PVC, PE, PP), rubber, cables, textiles, and composite sheets. |

| 6 |

Energy Efficiency |

|

The servo motor’s regenerative braking system reduces energy consumption by up to 30% compared to conventional AC motor systems, aligning with sustainable manufacturing goals. |

| 7 |

Durable and Low-Maintenance Build |

|

High-Strength Components: Stainless steel frame, wear-resistant polyurethane belts, and precision bearings ensure longevity in harsh environments. Self-Cleaning Mechanism: Minimizes debris buildup, reducing downtime for maintenance. |

| 8 |

Safety and Compliance |

|

Emergency Stop and Overload Protection: Safeguards both operators and equipment. CE/ISO Certified: Meets global industrial safety and quality standards. |

Applications

The Servo Belt Haul-Off Machine is a versatile asset across industries:

1.Plastic Extrusion: Precise pulling of pipes, profiles, and sheets in PVC, HDPE, or ABS production.

2.Cable Manufacturing: Gentle traction for fiber optic cables, wires, and insulated conductors.

3.Rubber Processing: Handling conveyor belts, seals, and automotive rubber components without deformation.

4.Packaging Films: Controlled haul-off for blown films, biodegradable wraps, and laminates.

5.Textile and Nonwovens: Tension management in fabric coating or composite material lines.

Technical Specifications

1.Traction Force: 50N to 5000N (customizable).

2.Speed Range: 0.1–150 m/min (adjustable via touchscreen).

3.Belt Material: PU, silicone, or rubber (anti-static/heat-resistant options available).

4.Power Supply: 380V/50Hz or customizable voltage.

5.Control System: Siemens/Allen-Bradley PLC with 10-inch color HMI.

6.Accuracy: ±0.1% speed stability, ±1N tension control.

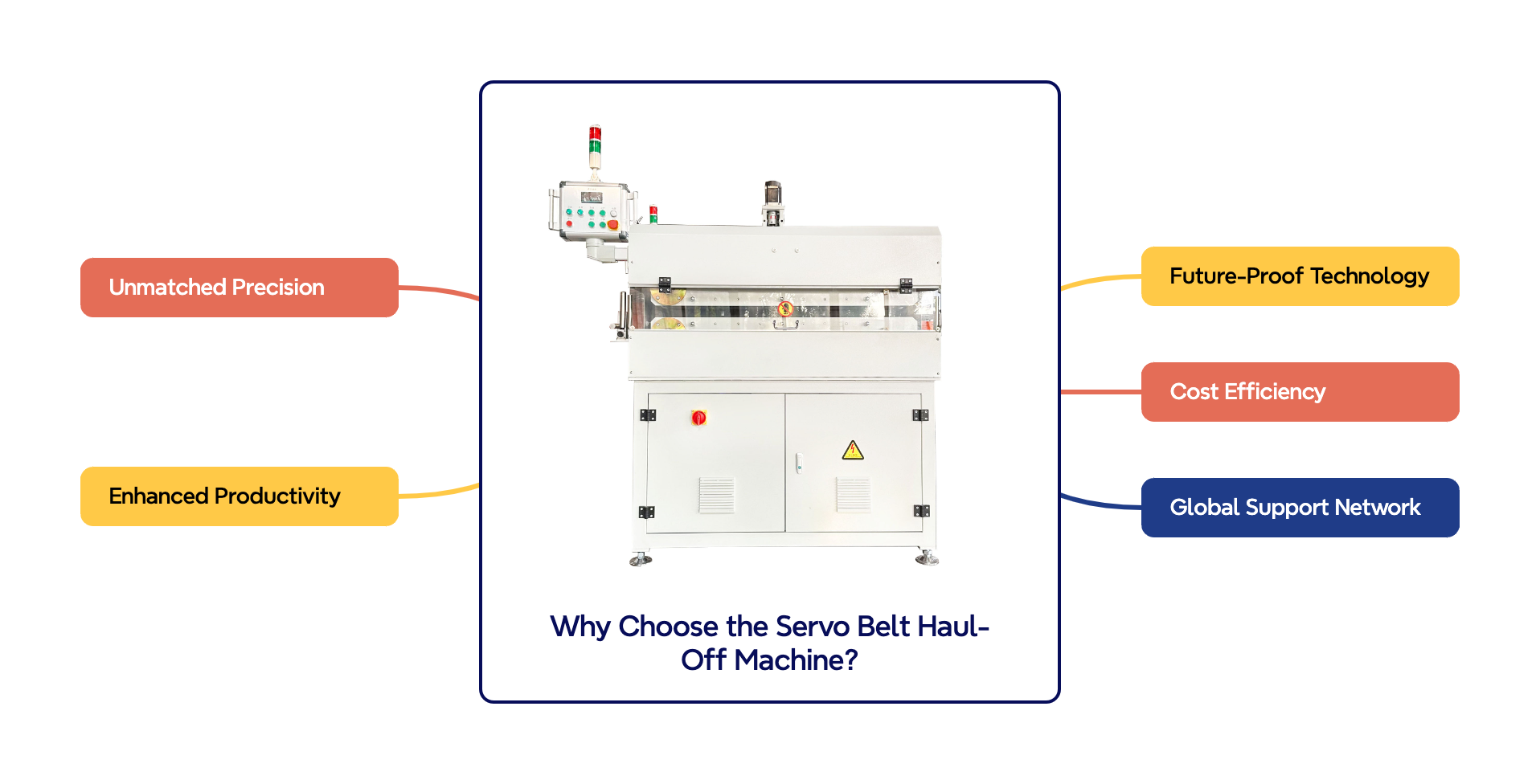

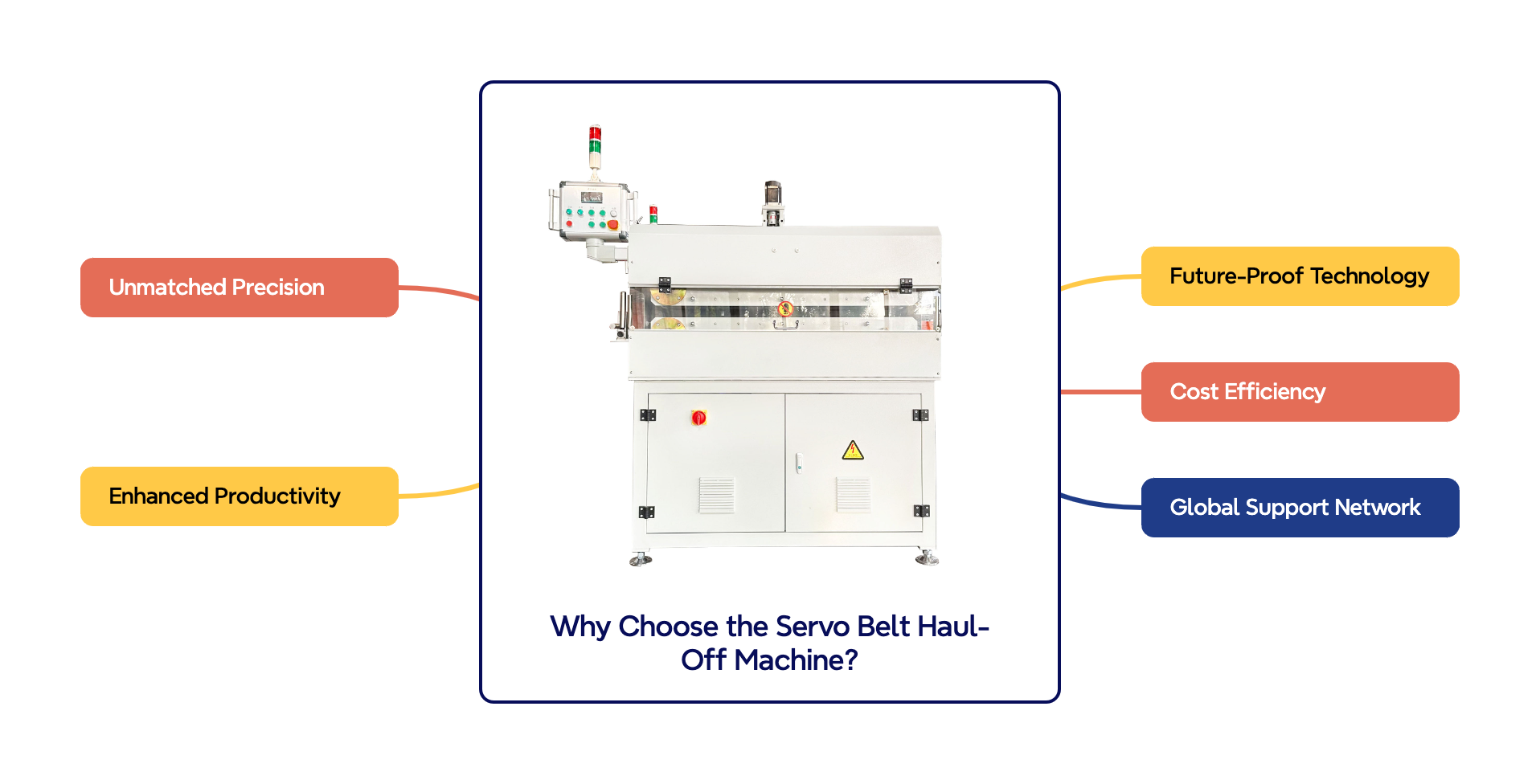

Why Choose the Servo Belt Haul-Off Machine?

| 1 |

Unmatched Precision |

|

Achieve flawless product dimensions and surface quality with servo-driven closed-loop control, critical for high-value applications like medical tubing or optical fibers. |

| 2 |

Enhanced Productivity |

|

Reduce material waste and downtime through seamless synchronization with upstream extruders, cutters, or winders. |

| 3 |

Future-Proof Technology |

|

Upgrade-ready design supports IoT connectivity and predictive maintenance, keeping your production line ahead in the Industry 4.0 era. |

| 4 |

Cost Efficiency |

|

Lower energy bills, reduced scrap rates, and minimal maintenance translate to rapid ROI. |

| 5 |

Global Support Network |

|

Backed by 24/7 technical support, on-site training, and a 1-year warranty, ensuring uninterrupted operations worldwide. |

The Servo Belt Haul-Off Machine redefines excellence in material handling, offering a perfect blend of precision, durability, and smart automation. Whether you’re optimizing an existing line or building a new smart factory, this machine empowers you to meet stringent quality standards while boosting efficiency and sustainability.

Invest today and experience the future of industrial traction technology—where every meter of production is controlled to perfection.

For custom configurations or industry-specific solutions, contact our engineering team to design a haul-off system tailored to your unique needs.

▏About Us

▏Corporate Culture

▏Cooperative Parts Supplier

▏Packing And Shipping